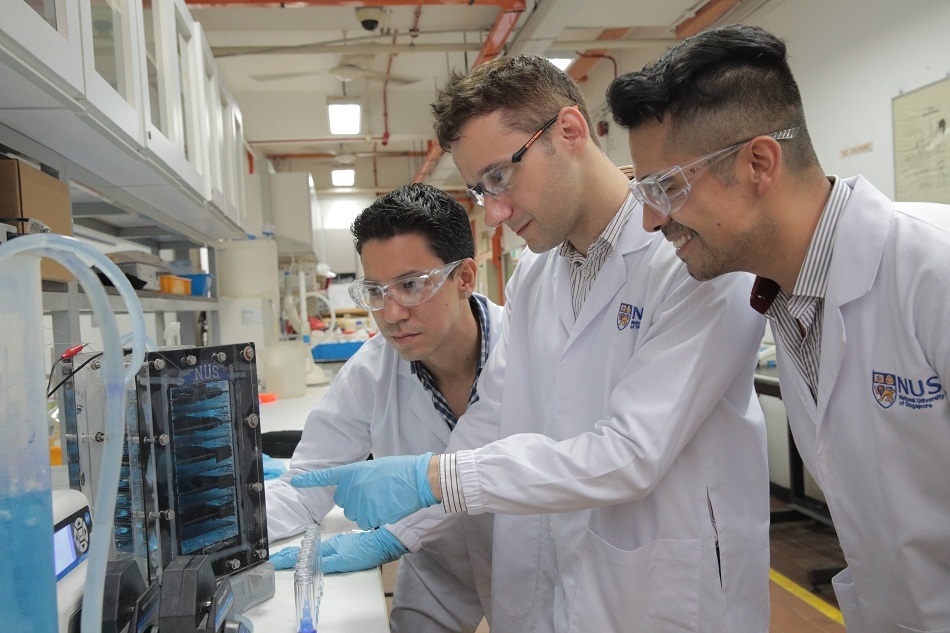

Researchers from NUS Faculty of Engineering have come up with a novel wastewater purification system that can remove up to 99 per cent of hard-to-treat organic compounds found in industrial wastewater. Image Credit: National University of Singapore

Researchers from NUS Faculty of Engineering have come up with a novel wastewater purification system that can remove up to 99 per cent of hard-to-treat organic compounds found in industrial wastewater. Image Credit: National University of Singapore

A low energy and cost effective wastewater purification system has been developed in Singapore by researchers who say their approach can remove up to 99% of obstinate impurities without using chemicals or producing sludge as a by-product.

Today’s industries increasingly require large quantities of high quality water for their processes, and the demand for ultrapure water while also maximising its reuse is growing. The global market for wastewater recycling and reuse reached almost $12.2 billion in 2016, a figure which is expected to grow to over $22 billion by 2021 – a compound annual growth of 13%.

A novel method – developed by scientists from the National University of Singapore (NUS) - uses electricity as a reagent for purification. It can eliminate up to 99% of hard-to-treat organic compounds found in industrial wastewater while operating on minimal power. As no secondary waste such as sludge is generated, no further processing or incineration is required.

Despite the great advances in wastewater treatment technologies, the removal of refractory organic compounds remains a costly and challenging process. Our invention provides an environmentally-friendly solution and helps to raise the overall standard of industrial wastewater treatment.

Olivier Lefebvre, Assistant Professor, The Department of Civil and Environmental Engineering, Faculty of Engineering, NUS

Wastewater contains organic compounds which are not biodegradable and can be harmful to humans and the environment: the electronics and pharmaceutical industry may have high concentrations of solvents and complex organic compounds in their wastewater, while farmland wastewater is likely to contain high levels of pesticides or herbicides.

“Our electrochemical system has shown that it can achieve complete mineralisation of any organic pollutant,” states Lefebvre. “This means the system can completely remove organic compounds in the wastewater by degrading them into water and carbon dioxide. This novel system can also be incorporated as a pre-treatment to an existing wastewater treatment scheme. It operates on low electrical power and the system could easily be combined with solar power and other purification methods such as using membranes and biological treatments.”

The NUS system uses electrochemistry to treat water and wastewater, without the need for supplementary chemicals to be added to the system. Wastewater is pumped into the system’s chamber and an electrical current is passed through. Electrodes in the chamber generate hydrogen peroxide and a hydroxyl radical – one of the most powerful oxidising agents – which will react with the complex organic compounds found in the water.

The hydrogen peroxide and hydroxyl radicals continuously degrade the complex compounds into smaller and simpler molecules until all the organic contaminants have been broken down into water and carbon dioxide; none of the hydrogen peroxide or hydroxyl radicals remain.

As well as benefitting farmland and the electronics and pharmaceutical industries, heavy manufacturing industries could use the new electrochemical system where ultrapure water is required for their processes, such as mining, oil and gas and the textile industries. It could also be utilized in the shipping industry to disinfect problematic ballast water from ships, to treat micro pollutants in domestic wastewater, or in the management of water purity in outdoor environments such as controlling algal growths in waterbodies and purifying landfill leachate.

When we started this project in July 2014, we aimed to use our expertise in electrochemistry and know-how in reactor design to create a robust, highly efficient and easy to operate water purification system for industrial wastewater that can reduce the need for third party processing or disposal.

Olivier Lefebvre

Our low-voltage electrochemical system can be installed in manufacturing plants of many different industries. The factories can easily reuse the treated water for their other processes and even control how pure the water is, according to their different needs.

The technique is now being tested on more types of industrial wastewater to further refine the design and improve the efficiency if the system. The team – who have applied to two patents for the technology – has also developed superior graphene electrode to help speed up the system’s water purification process, and are seeking to collaborate with industrial partners to commercialise the technology.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.