Dec 18 2017

Bituminous coal contains more than 90% of organic fuels in the Earth’s lithosphere. By burning coal and other fossil fuels one can obtain electrical power (which is largely happening at HPPs).

However, the existing generation techniques are not efficient, not good for the environment, and very resource-demanding (i.e. producing too much waste). Coal production and burning cause air and soil pollution and unfavorably impact flora and fauna.

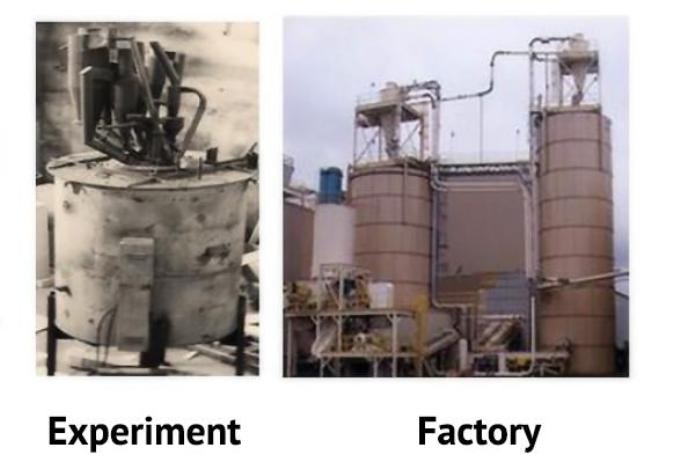

Mini coal-fired CHP plant on the basis of synthesis gas generator (CO + H2) and electrochemical current generator (experiment/factory). (Credit - Sergey Shcheklein)

Mini coal-fired CHP plant on the basis of synthesis gas generator (CO + H2) and electrochemical current generator (experiment/factory). (Credit - Sergey Shcheklein)

If fossil fuels could be directly turned into electrical energy, this would streamline and at the same time enhance the structure of electrical power plants. This type of direct conversion is possible with the use of electrochemical generators fueled with natural gas or combinations with similar composition.

The researchers recommended an uncommon scheme for the creation of syngas (a mixture of carbon monoxide and hydrogen that is used as a substitute for natural fuels) from bituminous coal and tested the efficiency of its use in an electrochemical generator.

It turned out that the new development may be employed rather than coal burning that is environmentally unfriendly and non-productive and make the process waste-free and greener. All products produced by the new unit may be either liquefied and buried or used in the manufacturing of industry-important substances such as ethylene, ethanol, or other hydrocarbons.

Our task was to replace a unique product - natural gas - with bituminous coal simultaneously improving energy and ecological characteristics of the units compared to the existing coal power plants. The technology proved to be very effective in joint generation of electrical and heat energy, while the configuration of the unit is much simpler.

Sergey Schecklein, Co-author, Doctor of Technical Sciences, Head of the Department of Nuclear Power Plants and Renewable Energy Sources of Ural Power Engineering Institute, UrFU

Syngas was produced in a unit with a boiling layer created at UrFU under the supervision of Professor Alexey Dubinin. It boosts the intensity of reactions numerous times leading to the production of a cleaner final product. After its purification the researchers put the product into a high-temperature solid oxide fuel cell where electrical energy was produced as a result of a reaction between oxygen and hydrogen in the air. The remaining carbon monoxide and hydrogen were moved to a waste heat boiler where heat energy needed for the technological process and generators was generated in the course of a burning reaction. WHB combustion products have no sulfur or cinder and thus no deep purification is required.

The research consisted of two phases: a theoretical and an experimental one. During the first phase the researchers considered energy, chemical, and physical processes that take place in the recommended unit scheme and established its key energy characteristics. Researchers also emphasized that the recommended technological scheme provided for the same fuel efficiency features as cutting-edge solutions using fuels in short supply, such as oil and gas.

On the experimental stage of the research, the team obtained syngas from coal fuel. It is quite an energy-intensive and easily transportable material. The authors examined the composition of the gas in a broad range of regimes and found out the area of highest boiling layer stability and efficient gas generation.

Research in this domain is being undertaken carried out all over the world with USA, Germany, and China among the leaders. Still, the Russian solution is distinctive. Presently, the team is in talks with industry partners about the development of demo units. The subsequent step will be the scaling of the unit and the unveiling of its mass production.

The obtained results may lay the ground for the new energy sector of the 21st century.

Sergey Schecklein