Feb 1 2018

Researchers at the Washington State University have discovered a method to efficiently produce hydrogen from water - a vital process to make clean energy more feasible.

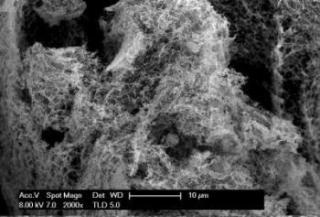

WSU researchers have found a way to create large amounts of inexpensive nanofoam catalysts that can facilitate the generation of hydrogen on a large scale by splitting water molecules. (Image credit: Washington State University)

WSU researchers have found a way to create large amounts of inexpensive nanofoam catalysts that can facilitate the generation of hydrogen on a large scale by splitting water molecules. (Image credit: Washington State University)

Using cheap nickel and iron, researchers created a very simple, five-minute technique to produce large quantities of a superior quality catalyst, necessary for the chemical reaction to split water.

They describe their technique in the February edition of the Nano Energy journal.

Energy conversion and storage is an answer to the clean energy economy. As wind and solar sources generate power irregularly, there is an acute need for ways to store and save the electricity they produce. One of the prospective ideas for storing renewable energy is to use the extra electricity produced from renewables to split water into hydrogen and oxygen. Hydrogen has numerous uses in industry and could be used to run hydrogen fuel-cell cars.

Industries have not extensively used the water splitting process, due to the high-priced cost of the precious metal catalysts that are required - usually ruthenium or platinum. Many of the approaches to split water also require a lot of energy, or the required catalyst materials break down too rapidly.

In their study, the researchers, guided by Professor Yuehe Lin in the School of Mechanical and Materials Engineering, used two amply available and inexpensive metals to develop a porous nanofoam that worked better than a majority of catalysts that presently are used, including those created from the precious metals. The catalyst they developed looks like a miniature sponge. With its unique atomic structure and many exposed surfaces across the material, the nanofoam can catalyze the vital reaction with less energy than other catalysts. The catalyst displayed very little loss in activity in a 12-hour stability test.

"We took a very simple approach that could be used easily in large-scale production," said Shaofang Fu, a WSU Ph.D. student who synthesized the catalyst and did most of the activity testing.

The WSU researchers partnered with researchers at Advanced Photon Source at Argonne National Laboratory and Pacific Northwest National Laboratory on the project.

"The advanced materials characterization facility at the national laboratories provided the deep understanding of the composition and structures of the catalysts," said Junhua Song, another WSU Ph.D. student who analyzed the catalyst characterization.

The team is currently seeking extra support to scale up their work for mass testing.

"This is just lab-scale testing, but this is very promising," said Lin.

The collaborative research was funded by a WSU startup grant and by the U.S. Department of Energy.