May 21 2018

The common factor between jet fuel and pantyhose or plastic soda bottles is that they are all products extracted at present from petroleum. Researchers from Sandia National Laboratories have developed an innovative technology based on bioengineered bacteria that could render the synthesis of all three from renewable plant sources economically viable.

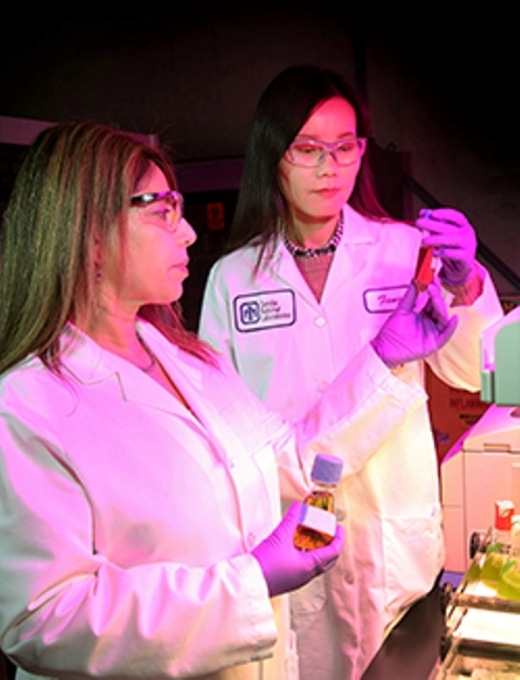

Sandia National Laboratories scientists Seema Singh (left) and Fang Liu hold vials of vanillin and fermentation broth, which are critical for turning plant matter into biofuels and other valuable chemicals. (Image credit: Dino Vournas)

Sandia National Laboratories scientists Seema Singh (left) and Fang Liu hold vials of vanillin and fermentation broth, which are critical for turning plant matter into biofuels and other valuable chemicals. (Image credit: Dino Vournas)

For a long time, efficient and cost-effective conversion of tough plant matter, known as lignin, has been a hindrance in the widespread use of the energy source and rendering it cost-competitive. Sandia bioengineer Seema Singh and two postdoctoral researchers, Weihua Wu, now at Lodo Therapeutics Corp., and Fang Liu, have integrated mechanisms from other known lignin degraders to engineer Escherichia coli into a productive and efficient bioconversion cell factory.

For years, we’ve been researching cost-effective ways to break down lignin and convert it into valuable platform chemicals. We applied our understanding of natural lignin degraders to E. coli because that bacterium grows fast and can survive harsh industrial processes.

Seema Singh, Sandia Bioengineer

The study, titled “Towards engineering E. coli with an autoregulatory system for lignin valorization,” was recently reported in the Proceedings of the National Academy of Sciences of the United States of America. Sandia’s Laboratory Directed Research and Development program supported the study.

Engineering a Costly Process into Profitability

Lignin is a plant cell wall component responsible for the exceptional strength of the cell walls. Although it contains enormous energy, deriving that energy has proven very expensive and complicated that the ensuing biofuel cannot compete economically with other forms of transportation energy.

Upon being disintegrated, lignin offers other benefits such as valuable platform chemicals that can be transformed into pharmaceuticals, plastics, nylon, and other products. The focus of further studies might be on demonstrating the synthesis of these products since they can balance biofuel and bioproduction economics. In Singh’s words, “they valorize lignin.”

Solving Three Problems: Cost, Toxicity, and Speed

Singh and her colleagues have overcome three challenges in converting lignin into platform chemicals.

The cost was the first challenge. In general, E. coli do not synthesize the enzymes essential for the conversion process. The bacteria must be induced by the researchers to produce the enzymes by adding an inducer to the fermentation broth. Although inducers are effective in activating enzyme production, they could be very expensive and hence are prohibitive for biorefineries.

The solution was to “circumvent the need for an expensive inducer by engineering the E. coli so that lignin-derived compounds such as vanillin serve as both the substrate and the inducer,” stated Singh.

Vanillin is not an evident alternative for an inducer. It is synthesized when lignin breaks down and, at higher concentrations, could possibly suppress the very E. coli striving to convert it. This gave rise to the second challenge: toxicity.

Our engineering turns the substrate toxicity problem on its head by enabling the very chemical that is toxic to the E. coli to initiate the complex process of lignin valorization. Once the vanillin in the fermentation broth activates the enzymes, the E. coli starts to convert the vanillin into catechol, our desired chemical, and the amount of vanillin never reaches a toxic level. It auto regulates.

Seema Singh, Sandia Bioengineer

Efficiency was the third challenge. Although the vanillin contained in the fermentation broth traveled across the cell membranes to be transformed by the enzymes, its motion was very slow and passive. To make this process rapid, the scientists searched for effective transporters from other microbes and bacteria, stated Wu.

“We borrowed a transporter design from another microbe and engineered it into E. coli, which helps pump the vanillin into the bacteria,” stated Liu. “It sounds pretty simple, but it took a lot of fine-tuning to make everything work together.”

Engineering solutions, such as those mentioned above, overcome efficiency and toxicity challenges and hence have the ability to make biofuel production economically feasible. The external inducer-free, auto-regulating technique for valorizing lignin is just one method on which scientists are working to enhance the biofuel-making procedure.

We have found this piece of the lignin valorization puzzle, providing a great starting point for future research into scalable, cost-effective solutions. Now we can work on producing greater quantities of platform chemicals, engineering pathways to new end products and considering microbial hosts other than E. coli.

Seema Singh, Sandia Bioengineer