May 23 2018

Concentrations of carbon dioxide in the atmosphere are produced mostly by burning fossil fuels and these have increased from 280 parts per million in the pre-industrial era to approximately 410 PPM in the present day.

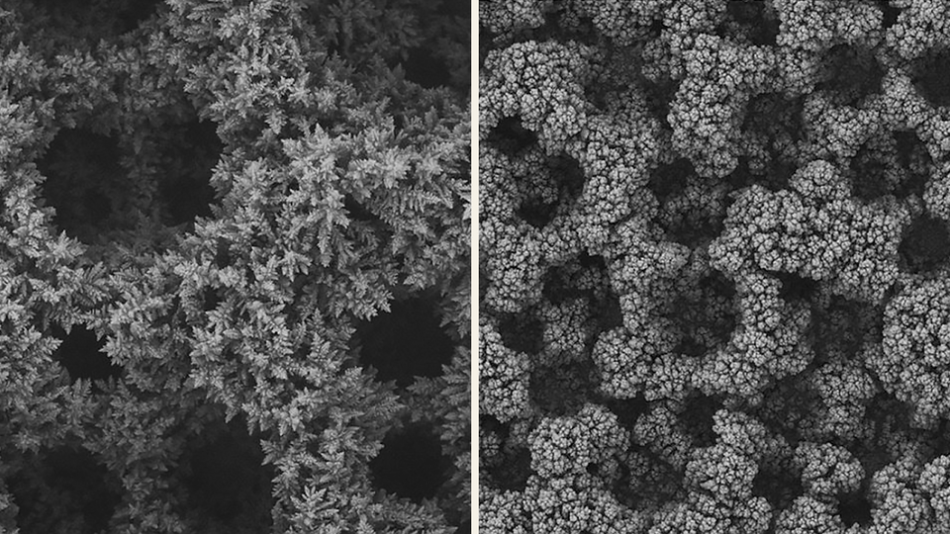

Microscopic views of copper foam when untreated (left) vs. coated with a polymer called polyacrylamide, which new research has shown can double the conversion of CO2 to ethylene. (Image credit: American Chemical Society / ACS Catalysis)

Microscopic views of copper foam when untreated (left) vs. coated with a polymer called polyacrylamide, which new research has shown can double the conversion of CO2 to ethylene. (Image credit: American Chemical Society / ACS Catalysis)

Besides that trend, the fact that the supply of fossil fuels is limited has nudged researchers to analyze ways for manufacturing plastic from CO2 instead of natural gas or petroleum - recycling the CO2 gas just the way plastic is being recycled.

Vitaly Alexandrov and team from Nebraska have now given a comprehensive catalyst-based method that is capable of doubling the amount of carbon dioxide transformed to ethylene, a vital constituent of the world’s most widely used plastic - polyethylene.

“The conversion of CO2 is very important to help offset the emissions that lead to global warming and other detrimental processes in the environment,” stated Alexandrov, assistant professor of chemical and biomolecular engineering.

Copper is considered the key contender for catalyzing chemical reactions that transform carbon dioxide to plastic-forming polymer molecules, upon application of voltage. However, some copper-based setups were unable to convert excess of about 15% of CO2 into ethylene—a yield that is inadequate to fulfill the industrial needs.

Therefore, scientists at Swansea University in Wales decided to coat copper with various polymers in order to enhance the efficiency. They discovered that the conversion rate of their copper foam went up from 13% to 26%, after they overlaid it with a polymer known as polyacrylamide.

Subsequently, Alexandrov and Konstantin Klyukin, a postdoctoral researcher, ran quantum mechanics-based simulations via Nebraska’s Holland Computing Center to explain why polyacrylamide surpassed the performance of other related polymers. They found that the polyacrylamide breaks up CO2, again assembles it into a pair of bonded C-O compounds, and subsequently stabilizes that new molecule as it drives more chemical reactions – those eventually producing ethylene.

CO2 is a very stubborn molecule because it has double bonds that are very difficult to break. That’s the most challenging part of trying to convert it to something else. You don’t want to spend too much energy converting it; otherwise, it’s a trade-off that becomes inefficient.

Vitaly Alexandrov

While scientists look to further increase that efficiency, they have a greater objective in mind: converting CO2 directly into the polyethylene that makes up plastic films, containers, and bags, Alexandrov said.

One of the things that experimentalists want is to go from synthesizing simple molecules, like ethylene, to very complicated molecules in one batch reaction. You put in CO2 catalysts, and you end up with polymer structures that you can sell in a store. But those molecules have very complicated structures. This is a first step toward understanding how we can (create them).

Vitaly Alexandrov

The study was authored by Alexandrov and Klyukin along with Swansea’s Enrico Andreoli, Sunyhik Ahn, Russell Wakeham, Jennifer Rudd, Aled Lewis and Shirin Alexander, together with Francesco Carla of the European Synchrotron Radiation Facility. The team’s paper featured in ACS Catalysis—a journal published by the American Chemical Society.

The Engineering and Physical Sciences Research Council and the Welsh Government Sêr Cymru Program provided support to the researchers.