Oct 30 2018

In an effort to enhance the efficiency of light electric vehicles (LEV), scientists at Simon Fraser University’s Surrey campus are designing state-of-the-art ‘passive’ cooling solutions for battery chargers in vehicles.

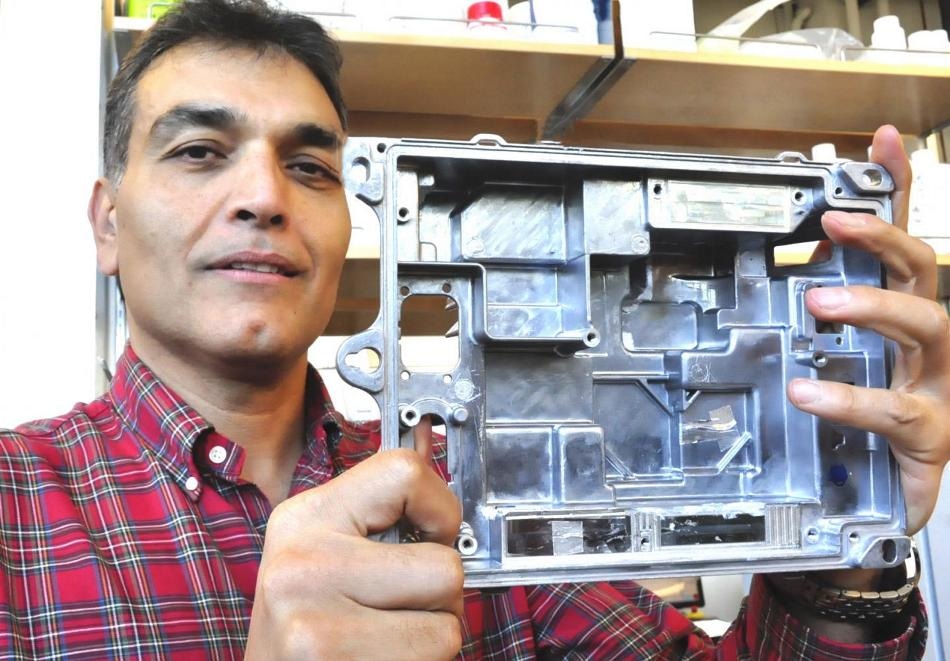

Simon Fraser University professor Majid Bahrami, of the School of Mechatronic Systems Engineering (MSE), with a prototype battery charger developed for light electric vehicles. His research has benefited from a recent Innovate B.C. award of $300,000. (Credit: SFU)

Simon Fraser University professor Majid Bahrami, of the School of Mechatronic Systems Engineering (MSE), with a prototype battery charger developed for light electric vehicles. His research has benefited from a recent Innovate B.C. award of $300,000. (Credit: SFU)

Graphite possesses excellent qualities that makes it both cost-effective and easier to manage in terms of thermal control. The material has been integral to the team's research thus far: “A major challenge to efficiently cooling components, which is critical for the reliable function of the power electronics, is the packed arrangement of components and limited available surface area for heat transfer,” states Majid Bahrami, a professor in SFU’s School of Mechatronic Systems Engineering (MSE).

Bahrami's team is developing a 1200W passively air-cooled LEV charger—the maximum charge for residential power oulets in North America. State-of-the-art graphite sheets are now being used by the researchers to improve the thermal performance, decrease electromagnetic interference, and eliminate parasitic cooling power. Parasitic cooling power is the power consumed by pumps, fans, and other cooling devices that brings down the temperature of a device, taking up as much as 15% of the device’s total energy usage.

In passive cooling, natural cooling mechanisms are used, such as free radiation and convection heat transfer. Passive cooling is also noise-free, greener, and more reliable (i.e. no parts can break down).

Graphite is also lightweight, resistant to corrosion, and has superior thermo-mechanical properties, such as heat removal capabilities. As a result, it is an excellent material for using in the auto industry and in the thermal management of power electronics, observes Bahrami.

Enhanced cooling by compact, light, and cost-effective heat removal systems is essential to the competitiveness of high-performance power electronics systems in the market,” he states. “It’s also desirable to replace the parasitic power consumption of fans with passively-cooled systems, which significantly improves efficiency, reliability (no fan failure) and reduces noise.

Majid Bahrami, Professor at School of Mechatronic Systems Engineering (MSE), Simon Fraser University

Bahrami holds a Canada Research Chair in Alternative Energy Conversion Systems, and he recently won an Innovate BC award of $300,000 to advance his partnerships with Terrella Energy Systems and Burnaby-based Delta-Q Technologies, to design and market the high-capacity chargers.

Based in British Columbia, Delta-Q is a global leader in the design and development of industrial chargers for lithium ion and lead-acid batteries, and their products are currently used in over two million devices worldwide.

The fourth largest exporter of raw graphite is Canada. The prposed graphite products are focused at the strategic $12 billion/year thermal management products and $17 billion/year industrial heat exchangers market, which, according to Bahrami, promise to transform the industry.

Bahrami’s study is one among four projects to share almost $1 million via Innovate BC’s Ignite program, which supports technologies that resolve issues within the natural resources and applied sciences sectors. Also funded were two other initiatives that involve SFU:

- In the 'cleantech' category, Steve Holdcroft, a chemistry professor, and his spin-off venture, Ionomr Innovations, are creating the most versatile and durable anion exchange membranes ever produced. The ground-breaking membrane will offer industry cleantech solutions in the treatment of wastewater and energy.

Earlier this year - as part of an investment of $26.3 million into four clean tech firms dedicated to protecting the environment - the federal government has allocated $2.3 million for Ionomr Innovations.

- In the agriculture/biotech category, Zamir Punja, a SFU biology professor, will develop a safer generation of plant-based pesticides obtained from Karanja and Neem oils. Punja is collaborating with Vancouver-based Terramera, a plant intelligence company, and UBC professor Juli Carillo in this initiative.

The team’s breakthrough technology, which is known as the Molecular Delivery System (MDS), boosts the effectiveness of oils and allows these environmentally-friendly pesticides to outpace their artificial chemical counterparts.