Nov 28 2018

Although the energy history of Pennsylvania is famous for the amounts of fossil fuels it has produced, it also filled with the environmental legacies of coal mining and, more recently, hydrofracturing.

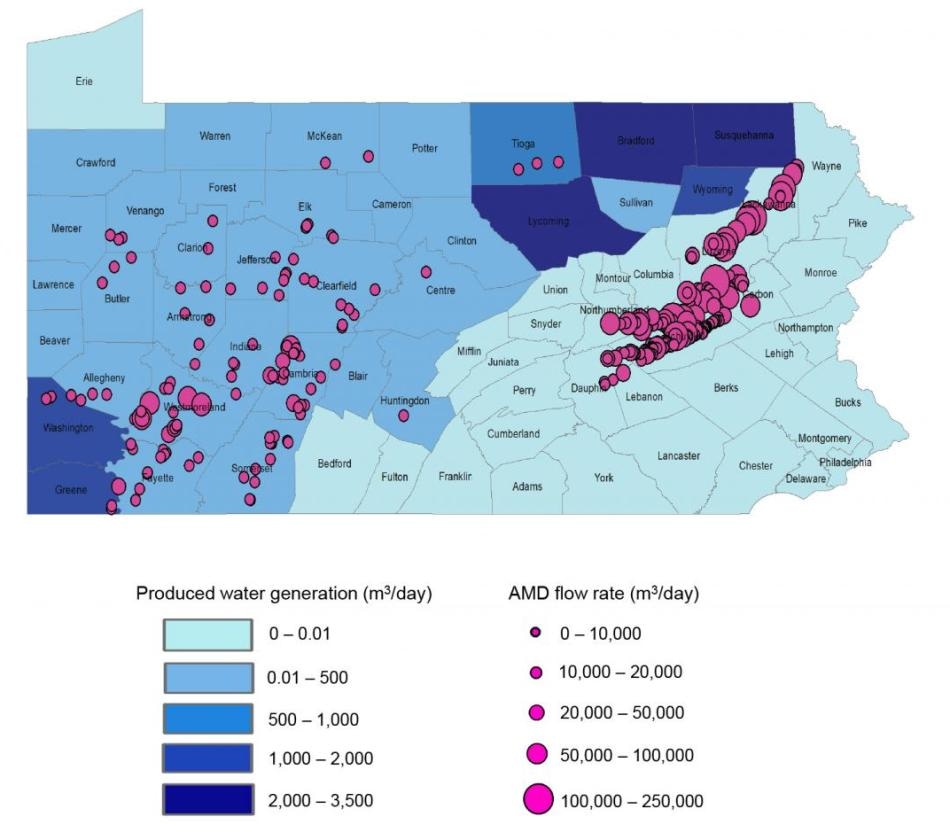

Map of Pennsylvania including the relative produced water generation volumes by county based on 2014 production data (indicated by the color gradient, m3/day) as well as the location and flow rate (m3/day) of AMD sites. (Image credit: Copyright 2018 American Chemical Society, reprinted with permission from Environmental Science & Technology)

Map of Pennsylvania including the relative produced water generation volumes by county based on 2014 production data (indicated by the color gradient, m3/day) as well as the location and flow rate (m3/day) of AMD sites. (Image credit: Copyright 2018 American Chemical Society, reprinted with permission from Environmental Science & Technology)

Water that enters into abandoned coal mines spread throughout the Commonwealth resurfaces as acid mine drainage (AMD), whereas freshwater used for fracturing or “fracking” oil and natural gas deposits reemerges as “produced” water contaminated with metals, salts, and radioactive material.

It is expensive to remediate both AMD and produced water, and federal law prohibits the disposal of produced water at municipal water treatment plants. However, a study by researchers from the University of Pittsburgh Swanson School of Engineering, reported recently in Environmental Science & Technology, has discovered that the co-treatment of both the fluids may not just solve two environmental issues at the same time, but also reduce the environmental effect of both legacy wastes.

The principal investigator of the study, titled “Life Cycle Impact and Benefit Tradeoffs of a Produced Water and Abandoned Mine Drainage Co-Treatment Process” (DOI: 10.1021/acs.est.8b03773), is Leanne Gilbertson, who is an assistant professor of civil and environmental engineering. The article, authored by graduate student Yan Wang, reports on a related study by her Swanson School colleagues, Radisav Vidic, the William Kepler Whiteford Professor and Department Chair of Civil and Environmental Engineering, and Associate Professor Vikas Khanna.

This study is the serendipitous result of three different researchers finding a common theme to unite the collaboration. Radisav’s group developed the method for co-treating AMD and produced water and he is a leading researcher in the field of produced water treatment via membrane distillation, while Vikas’s group focuses on complex systems analysis. My expertise in life cycle assessment brings a new perspective to these industries and a way to quantify the environmental and human health impact tradeoffs of alternative approaches to utilizing these two wastewaters.

Dr Leanne Gilbertson, Assistant Professor of Civil and Environmental Engineering, University of Pittsburgh Swanson School of Engineering.

The focus of Dr Gilbertson and her team was on a five-county region of southwestern Pennsylvania affected by both AMD and hydrofracturing—Allegheny, Fayette, Greene, Washington, and Westmoreland counties. The research targeted at three crucial, mutual aspects of remediation—co-treatment of AMD and produced water, transportation of water to and from drill sites and mine, and preventing the discharge of AMD into the environment. Dr Gilbertson’s LCA discovered that co-treatment of produced water and AMD is advantageous since, while the chemical composition of each fluid differs from site to site, the two byproducts include opposite amounts of barium and sulfates which, upon being combined, can be eliminated through precipitation. The ensuing fluid can subsequently be used to replace freshwater in future fracking operations, and the barite produced in this process can be used in drilling operations.

According to Dr Gilbertson, this result is significant because it produces value out of two important waste products and prevents the environmental effects of AMD.

While the combined produced water volume from fracking is 4,450 cubic meters per day, there is a staggering 281,000 cubic meters of orphaned AMD produced daily in the region. Mitigating the two via co-treatment would result in reduced freshwater use and become a net environmental benefit.

Dr Leanne Gilbertson, Assistant Professor of Civil and Environmental Engineering, University of Pittsburgh Swanson School of Engineering.

Although the co-treatment has a potential positive effect, the transportation of fluids between mining and drilling sites could lead to a considerable negative tradeoff. It will be a balance between the intended and current handling of produced water, which is usually transported long distances for treatment, or out of state for disposal through large trucks logging several hundred thousand miles per year.

In order to reduce these significant effects, not only including fuel use but also road wear and truck exhaust, Dr Khanna and his PhD student, Sakineh Tavakoli, created a model for the identification of the ideal locations for co-treatment sites between AMD and gas wells in the five-county region. Despite the fact that costs related to optimized co-treatment may be higher compared to the use of freshwater, the environmental advantages could be substantial. Another prospective option being piloted at present by Drs Vidic and Khanna is a mobile membrane distillation system that would be powered by waste heat produced during drilling to treat produced water on site.

Despite the fact that the optimization model was created using mining and gas well sites in the five-county region, the scientists state that this strategy can be applied to other regions in Pennsylvania, and throughout the United Stated using similar data.

Ms Wang stated that the innovative aspect of this study is that the group made efforts to quantify the advantages of not releasing AMD into ecosystems and the environment.

These are ‘credits’ to the system that you wouldn’t necessarily think about. For example, by utilizing AMD as a fracking fluid, we’re greatly reducing the amount of freshwater that would be wasted. Similarly, by optimizing transportation routes and developing mobile treatment sites, we are significantly reducing the environmental impact of long-haul trucking. Most importantly, by using AMD as a resource, we are helping to mitigate a legacy waste from the environment that then improves remediation efforts. In short, the cascade effect of co-treating these two waste products can be a net benefit for Pennsylvania.

Yan Wang, Graduate Student, University of Pittsburgh Swanson School of Engineering.