Dec 11 2018

High-quality bioplastic leader Bio-on, and Gruppo Hera, one of Italy’s major multi-utility providers, have struck a deal to take 90% and 10% shares, respectively (with the likelihood of Hera increasing its share to 49.9%) in LUX-ON, the new company founded by Bio-on aiming to transform the manufacture of PHAs biopolymers using CO2 taken from the atmosphere and generating energy without the need of fossil fuels. The new technology created by Bio-on envisages using CO2 as a zero cost “raw material”, along with those already used to create Bio-on bioplastic: fruit and potato waste, sugar beet and sugar cane molasses, carbohydrates, glycerol and waste frying oil. Using CO2 will also help lower the amount of CO2 in the atmosphere.

Credit: LUX-ON

Credit: LUX-ON

The laboratories and first plant of the new LUX-ON project will be constructed by the end of 2019 close to the Bio-on Plants industrial facility at Castel San Pietro Terme (Bologna). It will be designed completely by Bio-on technicians in partnership with Hera, with carbon capture plants and a production unit using renewable solar energy. The progress of the technology will be aided by the fact that a number of the principles and equipment used in the standard technology can also be employed in LUX-ON’s new production systems. This is why the development and pre-industrial phase will be a lot faster than normal. The plant will occupy an area of 1,500 m2, 600 m2 of which is covered, and will have a versatile production capacity that can be rapidly expanded.

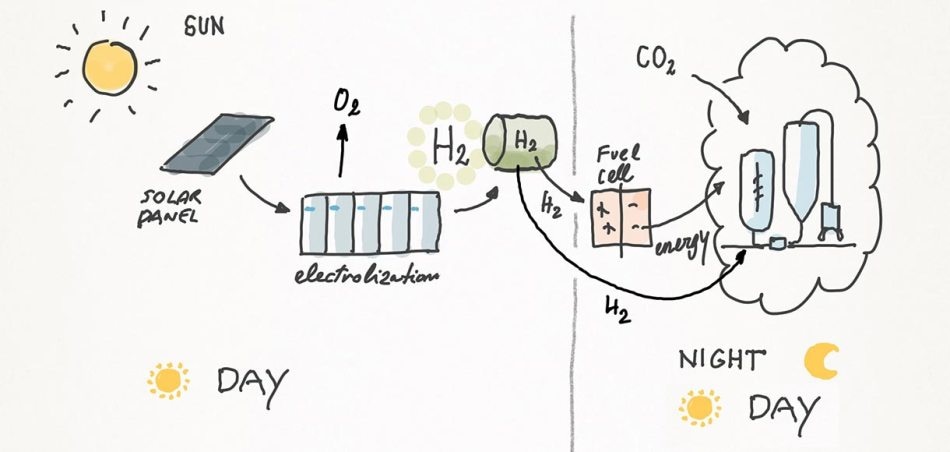

The electric energy used in LUX-ON’s ground-breaking production process will be generated by photovoltaic systems which, aside from directly powering production, will also deliver storable energy for nocturnal power (24/7 production). For energy storage, partnerships will be entered into with global experts in hydrogen (H) technology. Hydrogen, a non-polluting gas, will be made from solar energy, stored and then turned to electric energy to power the plant when the solar panels are not operational, i.e. at night or when sunlight is poor.

We are extremely pleased to work with HERA. The great technological innovation used at LUX-ON enables us to increase the industrial sustainability of a new production concept. We are particularly proud to realise humanity’s dream to capture CO2 from the atmosphere and produce innovative materials like our PHAs biopolymer. We are ready to face this new challenge, which will further extend our client base in the coming years, consolidating Italy’s global leadership in high-quality biopolymer production.

Marco Astorri, Chairman and CEO, Bio-on S.p.A.

Following a year of huge agreements, rapidly growing company Bio-on is set to start 2019 with new strategic projects, including its partnership with Hera.

The agreement also predicts a second development line directed at finding sustainable by-products for biopolymer production. Renamed PHA-CEL by Hera, this consists in revolutionizing cutting and cropping cellulose into simple sugars that can then be used in fermentation following an enzymatic treatment. This method is doable because of the treatment technology, created by Gruppo Hera, which is also evaluating how to apply it to biogas and biomethane manufacture from cuttings and prunings.

All the PHAs (polyhydroxyalkanoates) created by Bio-on are produced from renewable plant sources without any competition with food supply chains, and from CO2 in the years ahead. They can substitute a number of conventional polymers presently made with petrochemical processes using hydrocarbons; they guarantee the same thermo-mechanical properties as traditional plastics with the benefit of being fully eco-sustainable and 100% naturally biodegradable.

The agreement between the two companies has emerged from an extremely dynamic territory that signifies the technological cutting edge in Italy to be exported worldwide.

For Gruppo Hera, which uses innovation and sustainability as the foundations of its multi-utility business, taking a share in the new company founded by Bio-on is the representation of a natural coming together of intentions and an alliance that we believe can be developed successfully beyond our territory and across various sectors. With the breadth and quality of our services, this agreement will give further, fundamental green credentials to a project like LUX-ON, which aims to change the bioplastics world, not to mention the joint commitment to transform cuttings and prunings. Considering that Hera collects 200 thousand tons of cuttings and prunings every year, which can be transformed into bioplastic using our technology, this sector has huge growth potential.

Tomaso Tommasi di Vignano, Executive President, Gruppo Hera.

BIO ON LUX ON ENG h264 0812