Feb 22 2019

A fuel cell working on hydrogen instead of gasoline has been credited for enabling the 2019 Toyota Mirai electric vehicle to produce zero emissions. However, the Mirai has hardly left California partially because the currently available fuel cell electrodes are produced from the most expensive element, platinum.

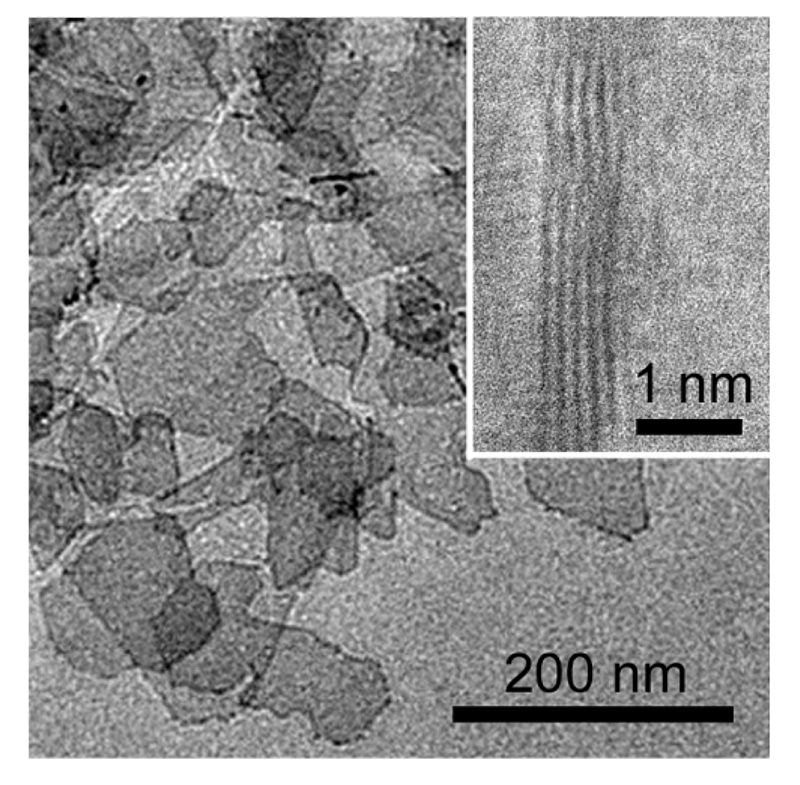

A platinum-like metal only five atomic layers thick is “just right” for optimizing the performance of a fuel cell electrode. (Image credit: Johns Hopkins University image/Lei Wang)

A platinum-like metal only five atomic layers thick is “just right” for optimizing the performance of a fuel cell electrode. (Image credit: Johns Hopkins University image/Lei Wang)

An increasing number of electric vehicles can be launched in the market if the use of platinum is reduced, which will eventually cut costs.

With some of its ideas taken from the fairy tale “Goldilocks,” a new method has been developed for analyzing the amount of metal needed for fuel cell electrodes. This new method involves using the forces on the surface of metal in order to detect the perfect electrode thickness.

There is exactly the right amount of metal that will give fuel cell electrodes the best properties. If they are too thick or too thin, the main reaction for deploying a fuel cell doesn't work as well, so there's sort of a Goldilocks principle here.

Jeffrey Greeley, Professor of Chemical Engineering, Purdue University.

Featured in the February 22nd issue of the journal Science, the study is a combined effort between Johns Hopkins University, Purdue University, and the University of California at Irvine.

The theory applied in this new method was tested on palladium, a metal more like platinum.

We’re essentially using force to tune the properties of thin metal sheets that make up electrocatalysts, which are part of the electrodes of fuel cells. The ultimate goal is to test this method on a variety of metals.

Jeffrey Greeley, Professor of Chemical Engineering, Purdue University.

Fuel cells transform hydrogen, along with a certain amount of oxygen, into electricity via an oxygen-reduction reaction that is initiated by an electrocatalyst. The surface of the electrocatalyst gets stressed when the correct thickness is detected and this in turn allows the electrocatalyst to execute this reaction in a much better way.

In the past, researchers have made attempts to use outside forces to compress or expand an electrocatalyst’s surface. However, this indeed risked making the electrocatalyst less stable.

As an alternative, Greeley’s group used computer simulations and predicted the possibility of manipulating the inherent force on the surface of a palladium electrocatalyst in order to obtain the best possible properties.

Based on the simulations, it was found that an electrocatalyst only five layers thick, with each layer being as thin as an atom, would be adequate to enhance performance.

Don’t fight forces, use them. This is kind of like how some structures in architecture don't need external beams or columns because tensional and compressive forces are distributed and balanced.

Zhenhua Zheng, Postdoctoral Researcher in Chemical Engineering, Purdue University.

Zheng is also the co-first and co-corresponding author of this study. The simulation predictions were confirmed by experiments conducted in Chao Wang’s lab at Johns Hopkins. These experiments discovered that the method has the potential to increase catalyst activity by 10 to 50 times, using 90% less of the metal than what is presently used in fuel cell electrodes.

The reason behind this is that the surface force on the atomically thin electrodes adjusts the strain, or distance existing between atoms, of the metal sheets, thus modifying their catalytic properties.

“By tuning the material's thickness, we were able to create more strain. This means you have more freedom to accelerate the reaction you want on the material’s surface,” stated Wang.

The study obtained support from several entities, including the U.S. Department of Energy, National Energy Research Scientific Computing Center, and the National Science Foundation.

The study supports Purdue’s Giant Leaps celebration, recognizing the university’s global developments made toward a sustainable economy and planet as part of Purdue’s 150th anniversary. This is considered to be one of the four themes of the yearlong celebration’s Ideas Festival, intended to showcase Purdue as an intellectual center resolving issues in the real world.