Mar 20 2019

The global aviation industry is known to require an estimated daily fuel of over five million barrels per day. As a result, this industry is remarkably energy-intensive and almost fully dependent on petroleum-based fuels.

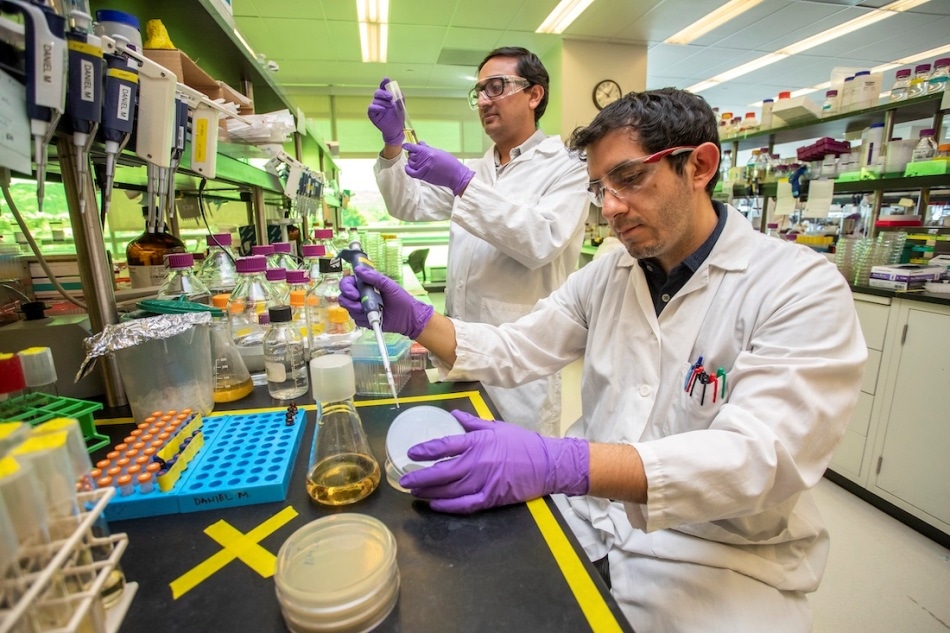

Project Scientist Daniel Mendez (right) and Postdoc Nawa Baral work on samples at JBEI, Lawrence Berkeley National Laboratory. Their research team is exploring how advances in production could make the plant-based jet fuels, currently under development at JBEI, price competitive with conventional fossil jet fuels. (Image credit: Marilyn Chung/Berkeley Lab)

Project Scientist Daniel Mendez (right) and Postdoc Nawa Baral work on samples at JBEI, Lawrence Berkeley National Laboratory. Their research team is exploring how advances in production could make the plant-based jet fuels, currently under development at JBEI, price competitive with conventional fossil jet fuels. (Image credit: Marilyn Chung/Berkeley Lab)

The aviation sector is different from other energy sectors like commercial and residential buildings, and ground transportation. This industry cannot use existing technologies to easily shift to renewable energy sources.

Now, a recent study carried out by researchers at the Department of Energy’s Lawrence Berkeley National Laboratory (Berkeley Lab) has demonstrated that sustainable plant-based bio-jet fuels can possibly offer a competitive substitute to traditional petroleum-based fuels, provided present scale-up and development initiatives continue to progress effectively.

The article titled, “Techno-economic analysis and life-cycle greenhouse gas mitigation cost of five routes to bio-jet fuel blendstocks,” has been recently reported in the journal, Energy & Environmental Science. It offers potential evidence that improving the biofuel production pipeline is really worth the effort. In this production pipeline, the carbohydrate-rich plant material is taken, followed by utilizing genetically modified bacteria to digest the separated sugars into energy-dense molecules, which are subsequently chemically changed into a fuel product.

It’s challenging to electrify aviation using batteries or fuel cells in part because of the weight restrictions on aircraft, so liquid biofuels have the potential to play a big role in greenhouse gas emissions reductions. The team at JBEI has been working on biological routes to advanced bio-jet fuel blends that are not only derived from plant-based sugars but also have attractive properties that could actually provide an advantage over conventional jet fuels.

Corinne Scown, Study Lead Author and Researcher, Energy Technologies Area, Berkeley Lab and Joint BioEnergy Institute, DOE

How to get fuel from plant material

At present, multidisciplinary groups from JBEI are working on improving each phase of the bio-jet fuel production process. Certain scientists are experts in designing the perfect source plants, called biomass, that produce a low proportion of lignin and a high proportion of carbohydrates Lignin is a kind of material that is currently more difficult to make. In the meantime, others are creating techniques to efficiently separate the carbohydrates in non-food biomass and decompose them into sugar molecules that can be subsequently digested by bacteria, or “bioconverted,” into a fuel molecule. In order to achieve the highest potential yield from bioconversion, yet another research team at JBEI is investigating the type of environmental and genetic factors that can render the modified bacteria more efficient.

Following the optimization of these stages, JBEI researchers can move the technologies to commercial partners who can subsequently alter and merge the fuels into products that can be readily used and then come up with plans to industrialize the level of production. However, since all these approaches will require extensive experimentations and innovations, Scown and her co-authors employed novel analysis techniques to check if the undertaking could really reach the ultimatum of a jet fuel alternative that can potentially be used by airlines.

Our hope is that early in the research stages, we can at least simulate what we think it would look like if you develop these fuel production routes to the point of maturity. If you were to push them to the ethanol benchmark—the technology to create ethanol from plant material like corn stalks, leaves, and cobs has been around a long time, and we can ferment sugars with a 90 percent efficiency—how close would this get us to the market price of petroleum fuels? That is important to know now. Thankfully, the answer is they can be viable. And we’ve identified improvements that need to happen all along the conversion process to make that happen.

Corinne Scown, Study Lead Author and Researcher, Energy Technologies Area, Berkeley Lab and Joint BioEnergy Institute, DOE

Imagining the production process at scale

Nawa Baral, co-author and JBEI postdoctoral fellow, informed that owing to the deconstruction of biomass and the fuel synthesis technologies devised at JBEI, the hypothetical expenses of bio-jet fuel have reduced gradually in the recent past and are presently down to $16 per gallon, as opposed to $300,000 for each gallon when JBEI was founded. The cost of regular jet fuel is approximately $2.50 per gallon.

In an effort to investigate how bio-jet fuel can possibly close the remaining price gap, the investigators applied intricate computer simulations that modeled the required technology and subsequent expenses of absolute and scaled-up production pathways at varied levels of efficiency and with an array of chemical inputs and biomass. In total, five different production pathways were simulated to four separate fuel molecules.

The outcomes demonstrated that all the five production pathways can certainly produce fuel products at the specified cost of $2.50 per gallon, provided producers are able to transform the remaining lignin into a useful chemical—something the JBEI team is presently working toward. Such a chemical can be sold to compensate for the biofuel cost. Additionally, the net cost of a gallon of biofuel can be further reduced if airlines were given a modest financial credit for reducing emission.

Post some industry analyses, the researchers also noted that airlines may agree to pay a premium of about fifty cents for each gallon, since all the four biofuels provide more amounts of energy per unit volume, implying that a plane can possibly fly farther on the same-sized tank.

The development of plant-based compounds that have a performance advantage over their petroleum-based counterparts is an important factor in determining their marketplace viability.

Blake Simmons, Study Co-Author and Chief Science and Technology Officer, Joint BioEnergy Institute

While these findings appear to be promising, more developments will be required to get the biofuel production technology to the gold-standard yields assumed in such simulations.

It’s clear that, to get these fuels to commercial viability, we need all hands on deck. But this analysis highlights the importance of multi-institutional, integrative research centers like JBEI because no group working on one phase of the process alone can make it happen.

Corinne Scown, Study Lead Author and Researcher, Energy Technologies Area, Berkeley Lab and Joint BioEnergy Institute, DOE

JBEI scientists Olga Kavvada, Daniel Mendez-Perez, Aindrila Mukhopadhyay, and Taek Soon Lee are the other co-authors of the study.

The DOE’s Office of Science funded JBEI, which was established with an aim to create economically-viable, carbon-neutral bioproducts and biofuels that use the sunlight energy preserved in biomass.