May 30 2019

University of Toronto Engineering researchers have created a new electrochemical path to change carbon dioxide (CO2) into valuable products such as plastics or jet fuel. The technology could considerably enhance the economics of capturing and recycling carbon straight from the air.

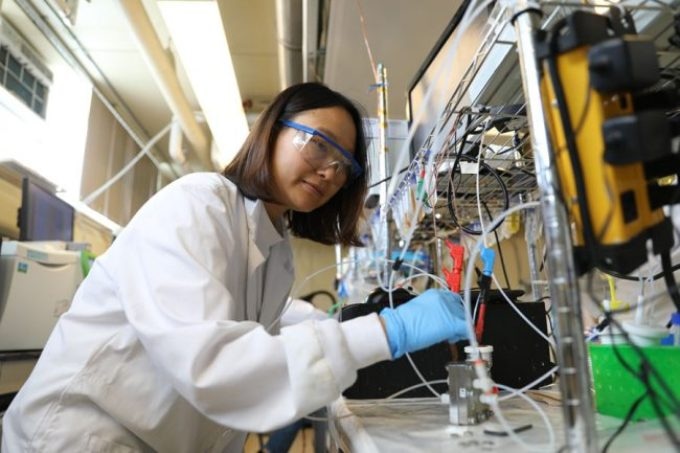

Geonhui Lee (ECE PhD candidate) operates an electrolyzer capable of transforming dissolved carbonate into CO2 and then into syngas. The device offers a new, shorter path for converting atmospheric carbon into commercially valuable products (Photo credit: Marit Mitchell)

Geonhui Lee (ECE PhD candidate) operates an electrolyzer capable of transforming dissolved carbonate into CO2 and then into syngas. The device offers a new, shorter path for converting atmospheric carbon into commercially valuable products (Photo credit: Marit Mitchell)

Today, it is technically possible to capture CO2 from air and, through a number of steps, convert it to commercial products. The challenge is that it takes a lot of energy to do so, which raises the cost and lowers the incentive. Our strategy increases the overall energy efficiency by avoiding some of the more energy-intensive losses.

Ted Sargent, Research Lead and Professor of ECE, University of Toronto Engineering

Direct-air carbon capture is an evolving technology whereby companies intend to create plastics or fuels from carbon that is already in the atmosphere, instead of from fossil fuels. Canadian company Carbon Engineering, which has set up a pilot plant in Squamish, B.C., traps CO2 by forcing air through an alkaline liquid solution. The CO2 dissolves in the liquid, developing a substance known as carbonate.

So as to be 100% recycled, the dissolved carbonate is usually converted back into CO2 gas, and then into chemical building blocks that form the foundation of fuels and plastics. One way to achieve this is to incorporate chemicals that change the carbonate into a solid salt. This salt powder is then heated at temperatures over 900 °C to create CO2 gas that can go through further transformations. The energy necessary for this heating pushes the cost of the resulting products upwards.

The U of T Engineering team’s substitute technique applies an electrolyzer, a device that applies electricity to trigger a chemical reaction. Having formerly used electrolyzers to create hydrogen from water, they understood that they could also be used to change dissolved carbonate right back into CO2, avoiding the in-between heating step completely.

“We used a bipolar membrane, a new electrolyzer design that is great at generating protons,” says Geonhui Lee, who along with postdoctoral fellow Y. Chris Li is among the lead authors of a new paper in ACS Energy Letters which describes the technique. “These protons were exactly what we needed to convert the carbonate back into CO2 gas.”

Their electrolyzer also has a silver-based catalyst that instantly changes the CO2 created into a gas mixture termed as syngas. Syngas is a regular chemical feedstock for the well-proven Fischer-Tropsch process, and can be freely converted into a wide range of products, including plastic precursors and jet fuel.

“This is the first known process that can go all the way from carbonate to syngas in a single step,” says Sargent.

While a number of types of electrolyzers have been used to change CO2 into chemical building blocks, not even one can effectively handle carbonate. Moreover, the fact that CO2 dissolved in liquid changes into carbonate so freely is a huge problem for current technologies.

“Once the CO2 turns into carbonate, it becomes inaccessible to traditional electrolyzers,” says Li. “That’s part of the reason why they have low yields and low efficiencies. Our system is unique in that it achieves 100% carbon utilization: no carbon is wasted. It also generates syngas as a single product at the outlet, minimizing the cost of product purification.”

In the laboratory, the team showed the ability to turn carbonate to syngas at complete energy efficiency of 35%, and the electrolyzer stayed stable for over six days of operation.

Sargent says that further work will be necessary to expand the process to the levels required for industrial application, but that the proof-of-concept research shows a feasible alternative path for direct-air carbon capture and application.

It goes a long way toward answering the question of whether it will ever be possible to use air-captured CO2 in a commercially compelling way. This is a key step toward closing the carbon loop.

Ted Sargent, Research Lead and Professor of ECE, University of Toronto Engineering