A precision-engineered replica model of a ‘smart bin’ aimed at cutting food waste has helped an aspiring designer and entrepreneur showcase his product to potential customers.

The intelligent food waste container designed by Daniel Lloyd is aimed at revolutionising the way businesses, local authorities and members of the public use their bins – dramatically reducing the amount of food needlessly thrown away each year.

In the UK, it is estimated that over eight million tonnes of food are wasted annually. A total of 85 per cent of food waste post-manufacture comes from households; this equates to £20 billion per year and an average of £810 per family per year.

Having graduated in Product Design Engineering from Liverpool John Moores University in 2017, Mr Lloyd secured funding for his waste management project as part of ‘The Environment Now’ - an Our Bright Future programme.

His start-up design consultancy, Daniel By Design, approached Hertfordshire-based Ogle Models to consult on, and complete the final semi-functional prototype.

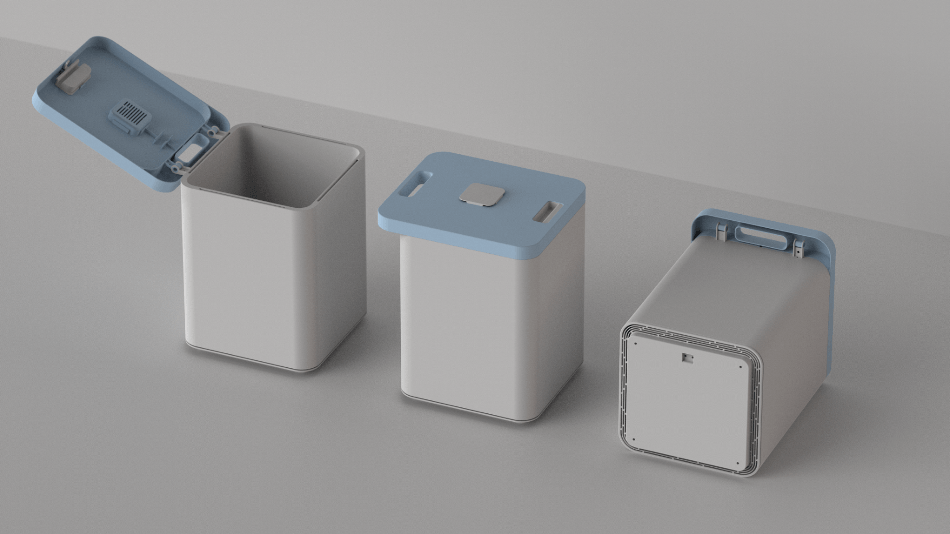

The project required precise finishing as well as functionality within the lid movements, both within a tight timescale. Initially, CAD designs of the wall thickness were altered to avoid potential breaking due to excessive deflecting under load.

The entire project was built using the SLA Ipro 8000 as the bed size (650 x 750 x 550 mm) allowed for all parts to be built at once, reducing lead times. SLA was also the preferred process due to the relative ease of finishing and the ability to print crisp lines and the specific features required for the project.

The skilled model making team at Ogle ensured a great surface finish by smoothing the surfaces ready for the paint process. As movement was required in the lid, the team had to be careful when rubbing down to maintain the crisp edges and make sure it was a good fit for assembled components.

From the client’s RAL reference, Ogle’s paint team began the custom paint project by consulting on the colour references to ensure the finishing looked exactly like the production part.

Following completion of the project, Daniel was invited to display the Food Waste Container at One Year In, New Designers 2018. The project has continued to get significant interest from both public and private sector organisations.

Mr Lloyd said: “I’d been recommended to Ogle by a friend and looked at their work online; it’s impressive. The team at Ogle were great.

“They offered loads of support to a first-time designer who wanted to get to know everything. I’m working towards developing a company that specialises in sustainable and social-impact projects. Ogle was an exceptional first-time partner.”

The waste system works by using technology enabling four outside waste containers to report daily on volume and mass of waste. The bins also feature ventilation units and carbon filters so that, if the containers are not due to be collected for a month, odours are reduced.