Jun 24 2019

The discoveries of essential scientific research are usually several steps away from a product that can be instantly brought to the general public. However, opportunity makes an early appearance every once in a while.

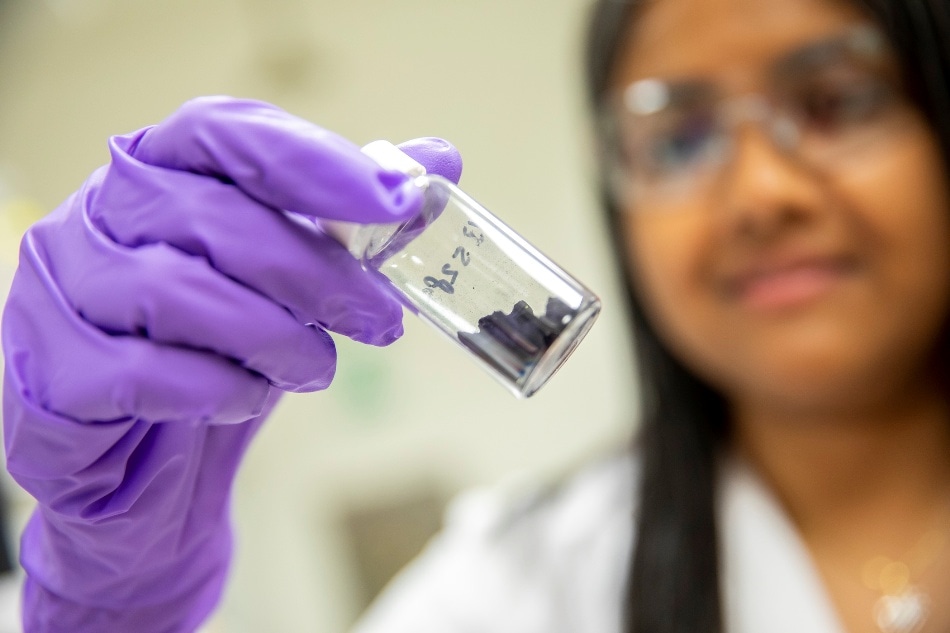

Lead researcher Aindrila Mukhopadhyay holds a vial of purified indigoidine crystals. (Image credit: Marilyn Chung/Berkeley Lab)

Lead researcher Aindrila Mukhopadhyay holds a vial of purified indigoidine crystals. (Image credit: Marilyn Chung/Berkeley Lab)

That was the case for a research team from the Joint BioEnergy Institute (JBEI) of the U.S. Department of Energy, whose out-of-the-box thinking when analyzing microbe-based bioproduction directly led to an environmentally friendly production platform for a new blue pigment known as indigoidine.

Indigo is a dye that is used globally for coloring a host of items, including denim. With a similar intensely saturated hue as artificial indigo, the fungi-produced indigoidine developed by the team may offer a substitute to a process that is predominately environmentally unfriendly.

Originally extracted from plants, most indigo used today is synthesized. These processes are efficient and inexpensive, but they often require toxic chemicals and generate a lot of dangerous waste. With our work we now have a way to efficiently produce a blue pigment that uses inexpensive, sustainable carbon sources instead of harsh precursors. And so far, the platform checks many of the boxes in its promise to be scaled-up for commercial markets.

Aindrila Mukhopadhyay, Lead Researcher, Joint BioEnergy Institute, U.S. Department of Energy

Mukhopadhyay directs the Host Engineering group at JBEI.

Significantly, commercial markets like those already have a substantial demand for what the researchers hope to supply. After the researchers met with several major stakeholders in the textile sector, they discovered that a number of companies are looking for more sustainably sourced pigments because awareness of the effects of traditional dyes has increased among the customers.

There seems to be a shift in society toward wanting better processes for creating everyday products. That’s exactly what JBEI is trying to do, using tools derived from biological systems— it just so happens that our engineered biological platform worked very well.

Maren Wehrs, Study First Author and Graduate Student, Joint BioEnergy Institute, U.S. Department of Energy

Wehrs has described the discovery, which has been recently reported in Green Chemistry.

The story started when the researchers set out to test how nonribosomal peptide synthetases (NRPSs) are possibly expressed by a hardy fungi species known as Rhodosporidium toruloides. NRPSs are large enzymes that are used by fungi and bacteria to assemble vital compounds.

The researchers analyzed the NRPS expression capability of the fungi by implanting a bacterial NRPS inside its genome. The team selected an NRPS that changes a pair of amino acid molecules into a blue pigment—indigoidine—which would make it easy to tell whether the strain engineering had worked or not. Quite easily, the culture would turn blue when the strain engineering works.

Where this experiment was concerned, indigoidine itself was not the major interest for the researchers. Rather, they were concentrating on the bigger picture—that is, looking for ways on how to harness the assembly line functionality of these enzymes to produce biosynthetic manufacturing pathways for useful organic compounds, for example, biofuels, and evaluating whether the fungi truly represented an excellent host species for producing these compounds.

However, when the researchers cultured their engineered strain, and observed the culture’s vivid blue color, they instantly knew that something remarkable had occurred.

With a typical titer of 86 g of indigoidine for each liter of bioreactor culture, the production of the strain—which the team dubbed as Bluebelle—is the highest to be ever reported to date. Other research teams, that also include the JBEI team, have produced the indigoidine through varied host microbes. In addition, the record-breaking yield was achieved from a culture process that utilizes precursor and nutrient inputs, which are sourced from sustainable plant materials. This fact further supports this achievement. Earlier pathways called for significantly more costly inputs but made roughly one-tenth the amount of indigoidine.

Apart from the promising uses of indigoidine, the study succeeded in its original objective of offering a possible production pathway for other kinds of NRPSs, something that is relatively more useful than any one product. Complex enzymes like these have numerous subunits that each is able to perform an expectable and distinct action in arranging a compound out of tinier molecules.

Researchers at JBEI and beyond are looking for ways to design enzymes that utilize the Lego block-like features of NRPSs to manufacture sophisticated bio-products that cannot be made easily today.

A big challenge is to get a microbe to efficiently express such enzymes. This host has huge potential to fulfill that need.

Aindrila Mukhopadhyay, Lead Researcher, Joint BioEnergy Institute, U.S. Department of Energy

The next steps of the researchers will be to define how indigoidine can possibly be utilized as a dye and to further explore the capabilities of R. toruloides.