Nov 25 2019

Whenever fossil fuels are burnt, they release a harmful pollutant. Now, an international group of researchers has developed a new, sophisticated material that captures this pollutant from the exhaust gas stream and changes it into valuable industrial chemicals using just air and water.

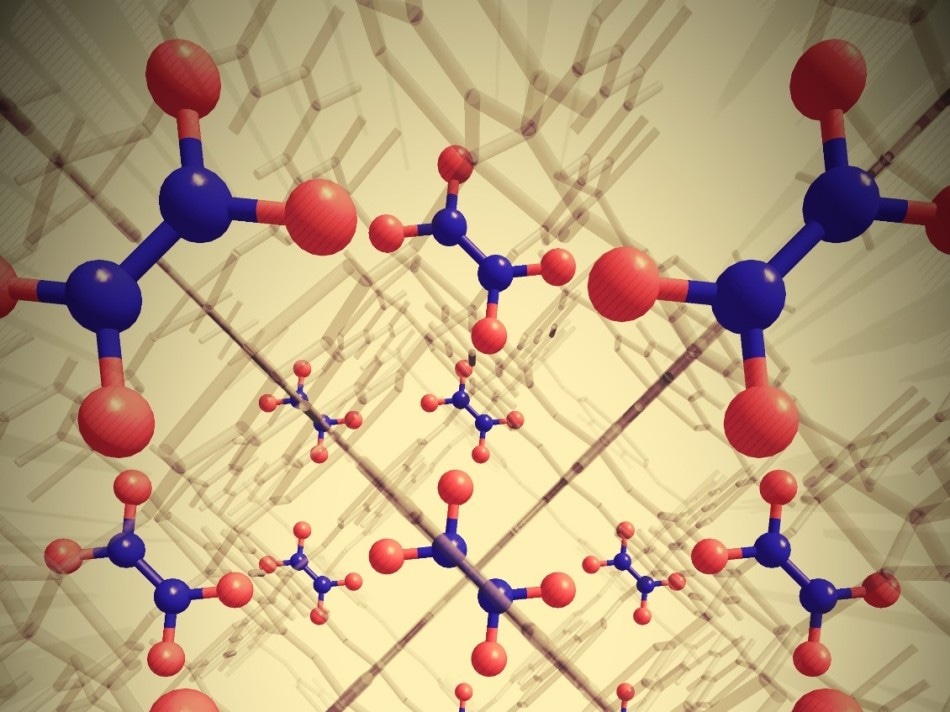

MFM-520. Image Credit: The University of Manchester.

MFM-520. Image Credit: The University of Manchester.

Headed by The University of Manchester, the researchers have created a new metal-organic framework (MOF) material that offers a selective and completely repeatable and reversible potential to trap nitrogen dioxide (NO2). NO2 is a harmful air pollutant that is specifically produced by the use of diesel and biofuel.

The NO2 gas can then be changed into nitric acid easily. Nitric acid is a multi-billion dollar sector that has applications such as nylon, rocket propellant, and agricultural fertilizer for crops.

MOFs are essentially small, three-dimensional (3D) porous structures that trap the gases within; they behave just like cages. The internal vacant spaces in these MOFs can be huge for their size—the surface area of just 1 g of material is equal to a football pitch.

To characterize the extremely efficient mechanism in the novel MOF material, the scientists used synchrotron X-ray diffraction and neutron scattering at the U.S. Department of Energy’s Berkeley National Laboratory and Oak Ridge National Laboratory, respectively.

The researchers also studied the mechanism of adsorption of the NO2 gas using the National Service for Electron Paramagnetic Resonance Spectroscopy at The University of Manchester. The technology could aid in controlling air pollution and thus help in resolving the negative effect of NO2 on the environment.

As stated in Nature Chemistry, the material, called MFM-520, is capable of capturing NO2 at ambient temperatures and pressures—even during flow and at trace concentrations—in the presence of carbon dioxide, sulfur dioxide, and moisture.

MFM-520 is a highly reactive pollutant in nature. But in spite of this fact, this pollutant can be completely regenerated numerous times either by degassing or by treating with water in the air—a kind of process that also changes the NO2 into nitric acid.

This is the first MOF to both capture and convert a toxic, gaseous air pollutant into a useful industrial commodity. It is also interesting that the highest rate of NO2 uptake by this MOF occurs at around 45 degrees Centigrade, which is about the temperature of automobile exhausts.

Dr Sihai Yang, Study Lead Author and Senior Lecturer, Department of Chemistry, The University of Manchester

According to Professor Martin Schröder, Vice-President and Dean of the Faculty of Science and Engineering at The University of Manchester, “The global market for nitric acid in 2016 was USD $2.5 billion, so there is a lot of potential for manufacturers of this MOF technology to recoup their costs and profit from the resulting nitric acid production. Especially since the only additives required are water and air.”

As part of the study, the researchers utilized computational methods and neutron spectroscopy at ORNL to accurately define the way MFM-520 captures the molecules of NO2.

This project is an excellent example of using neutron science to study the structure and activity of molecules inside porous materials.

Timmy Ramirez-Cuesta, Coordinator for the Chemistry and Catalysis Initiative, Neutron Sciences Directorate, Oak Ridge National Laboratory

Ramirez-Cuesta is also the co-author of the study.

He continued, “Thanks to the penetrating power of neutrons, we tracked how the nitrogen dioxide molecules arranged and moved inside the pores of the material, and studied the effects they had on the entire MOF structure.”

The characterisation of the mechanism responsible for the high, rapid uptake of NO2 will inform future designs of improved materials to capture air pollutants.

Jiangnan Li, Study First Author and PhD Student, The University of Manchester

Earlier, it was difficult to capture harmful and greenhouse gases from the atmosphere because their concentrations were comparatively low. Moreover, the atmospheric water also competes and most often can negatively impact the isolation of targeted gas molecules from other types of gases.

Yet another problem was to identify a practical method to filter out and change the trapped gases into useful, value-added products. Most of these challenges can be addressed by the MFM-520 material.