A team of Covestro and RWTH Aachen has developed a new method for the use of carbon dioxide as a raw material, which ranks among the year’s best innovations in Germany. The new technologies make CO2 usable in plastics production and thereby reduces fossil resources like petroleum. They made it to the final round of the renowned German President's Award for Innovation in Science and Technology, which was presented in Berlin by Federal President Frank-Walter Steinmeier.

Using CO2 for Resource Conservation and Circular Economy

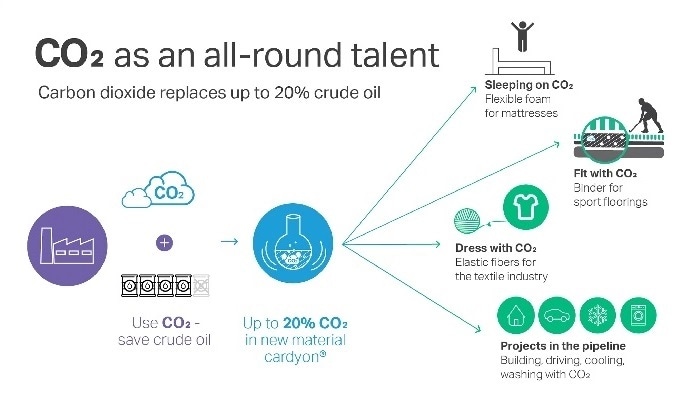

According to team spokesperson Gürtler, using CO2 contributes to resource conservation by partially replacing the conventional raw material oil as the sole source of carbon. At the same time, it also makes it possible to produce more recyclable plastics whose components could be recycled more easily. In addition, the circular economy will benefit from the reuse of carbon dioxide.

“We also see considerable potential for value creation by using CO2,” stressed Gürtler, who is responsible for developing new methods and products at Covestro.

High-Quality Plastics and Other Applications

“With the new platform technology, CO2 can be used to develop a wide range of high-quality plastics,” explained Berit Stange. She is responsible for the circular economy in a leading position at Covestro and supports the marketing of the new method.

Chemical precursors with CO2 (polyols) are already on the market for producing soft foams (polyurethane) for mattresses and soft furniture. The new material cardyon® is now also used for sports flooring. Further areas of application include elastic textile fibers, insulation and car interior applications.

Custom-Made Catalyst

The use of CO2 was conceived in a research breakthrough. The difficulty that CO2 has in forming chemical bonds was a great challenge that was overcome. The solution was essentially found in a custom-made catalyst. It controls the chemical reaction so that it is environmentally friendly, economical and efficient.

This breakthrough was achieved by experts from Covestro and the CAT Catalytic Center, a research institute jointly operated by the company and the RWTH Aachen. Experts had been searching for such a catalyst for decades.

Covestro Among the Three Finalists

“Team CO2”, which made it among the three finalists and presented its innovation on stage in Berlin, consists of Dr. Christoph Gürtler and Dr. Berit Stange from Covestro, as well as Professor Walter Leitner, who teaches and performs research at RWTH Aachen and the Max-Planck Institute for Chemical Energy Conversion. The trio played a major role in the development and market launch of this innovative method. The German President’s Prize (or “Deutscher Zukunftspreis”) is handed out annually for outstanding achievements in technology and natural science that lead to market-ready products.

Avoiding Crude Oil as Central Resource

“We are very happy that we made it to the final round. The idea behind CO2 innovation fits in perfectly with the times Fossil sources, such as crude oil can no longer be the industry’s central resource if the world is heading towards a future that is low in greenhouse gases," said Covestro CEO Dr. Markus Steilemann.

“The award has encouraged us to continue working intensively on developing innovative solutions for greater sustainability in many areas. Together with partners from the business and scientific community, we will continue to forge ahead with the development of alternative resources, such as CO2. As a chemicals and research location, Germany can make a name for itself in this field.”