Jan 22 2020

The process of collecting, purifying, and disposing of polluted water requires a lot of energy. Certain pollutants, such as arsenic, occur in low concentrations, reinforcing the need for much more energy-intensive selective removal processes.

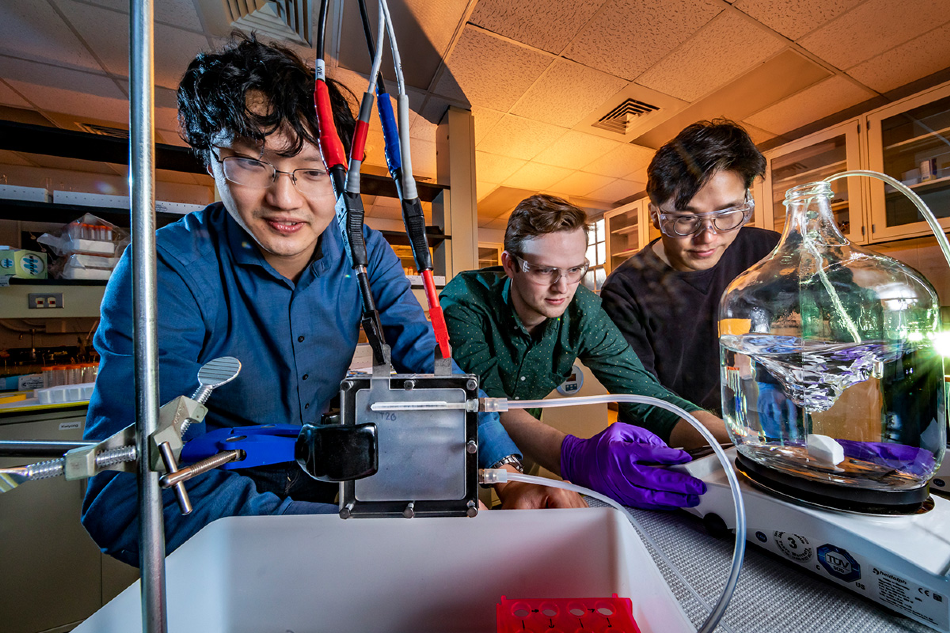

Professor Xiao Su, left, graduate student Stephen Cotty, center, and postdoctoral researcher Kwiyong Kim have developed an energy-efficient device that selectively absorbs a highly toxic form of arsenic in water and converts it into a far less toxic form. Image Credit: Fred Zwicky.

Professor Xiao Su, left, graduate student Stephen Cotty, center, and postdoctoral researcher Kwiyong Kim have developed an energy-efficient device that selectively absorbs a highly toxic form of arsenic in water and converts it into a far less toxic form. Image Credit: Fred Zwicky.

Scientists have now addressed the relationship between water and energy in a recent study, by developing a device that is capable of purifying and remediating water contaminated with arsenic in just one step.

The device uses specialized polymer electrodes to lower the arsenic content in water by more than 90% while utilizing energy that is almost 10 times less than the energy used by other techniques. The study results have been published in the Advanced Materials journal.

According to the scientists, arsenic is an element that occurs naturally and enters lakes, streams, and aquifers; water that reacts with arsenic-containing rocks is believed to be extremely toxic. This is a universal problem that impacts over 200 million people in 70 nations.

But according to Xiao Su, a chemical and biomolecular engineering professor at the University of Illinois who led the study, not all forms of arsenic are the same. Arsenite is the most toxic form of arsenic and is extremely reactive with biological tissues. However, it changes to a less toxic form, known as arsenate, via a simple oxidation reaction.

We can remove arsenite from water using absorbents, specialized membranes or evaporation, but these are all very energy-intensive processes that ultimately leave behind a lot of toxic waste. By having a device that can capture arsenite with a high selectivity and convert it to a less toxic form, we can reduce the toxicity of the waste while purifying the water.

Xiao Su, Study Lead and Assistant Professor, Chemical and Biomolecular Engineering, University of Illinois

The proof-of-concept device functions by combining the contaminant separation and reaction steps inside a single unit that includes an electrocatalytic cell—just like a battery—by making use of redox-active polymers.

As the contaminated water penetrates the device, the arsenite is selectively captured by the first polymer electrode and sent to the other polymer electrode. The second polymer electrode oxidizes the arsenite or strips of two of its electrons to form arsenate. Pure water exits the device, and the arsenate waste is concentrated for subsequent disposal, stated Su.

The process is powered by electrochemical reactions, so the device does not require a lot of electricity to run and allows for the reuse of the electrodes based only on electrochemical potential.

Xiao Su, Study Lead and Assistant Professor, Chemical and Biomolecular Engineering, University of Illinois

Su continued, “Combining the separation and reaction steps into one device is an example of what we call processes intensification, which we believe is an important approach for addressing environmental concerns related to energy and water—in particular, the amount of energy it takes to purify and remediate contaminated water.”

According to the research team, besides enhanced energy efficiency and sustainability, the new electrochemical method offers benefits for field deployment. Solar panels can be used to operate the device in regions with a limited supply of electricity—for example, in parts of rural Bangladesh, where more than 60% of the population is affected by water contaminated with arsenic.

However, challenges have to be tackled before the device can be prepared for real-world implementation.

We need to increase the stability of the electrodes because this process will need to be cycled many times while running. We’re using very specialized, highly advanced polymer materials for the electrodes. However, we need to make sure we design them to be not only highly selective for arsenic, but also very stable and robust so that they do not need to be replaced constantly. This will require further chemical development to overcome.

Xiao Su, Assistant Professor, Chemical and Biomolecular Engineering, University of Illinois

Su is also affiliated with the Beckman Institute for Advanced Science and Technology at the University of Illinois.

The study’s lead authors are Kwiyong Kim, a postdoctoral researcher, and Stephen Cotty, a graduate student, both belonging to Su’s group. Chia-Hung Hou, a professor from the Graduate Institute of Environmental Engineering at the National University of Taiwan, teamed up with the University of Illinois in this study.

The study was supported by the National Science Foundation and the University of Illinois.