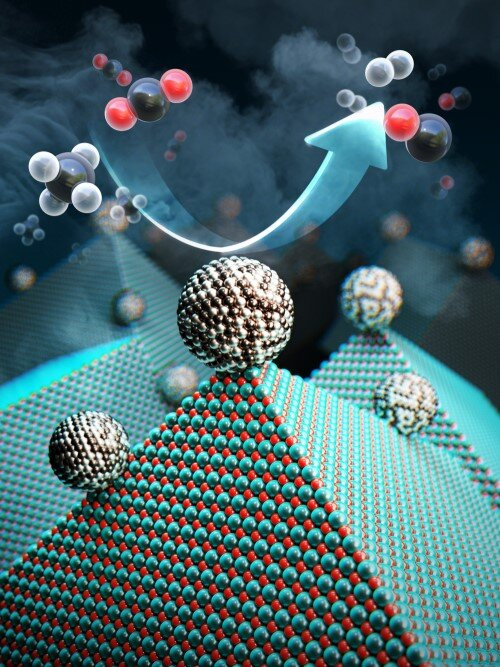

The catalyst that recycles greenhouse gases into ingredients that can be used in fuel, hydrogen gas and other chemicals. Image Credit: The Korea Advanced Institute of Science and Technology (KAIST)

The catalyst that recycles greenhouse gases into ingredients that can be used in fuel, hydrogen gas and other chemicals. Image Credit: The Korea Advanced Institute of Science and Technology (KAIST)

Researchers at KAIST have developed a new long-lasting catalyst capable of recycling greenhouse gases into ingredients for use in hydrogen gas, fuel, and other chemicals.

Taking one step closer towards a circular carbon economy is a high-priority for scientists and policymakers who continue to invest their belief in the future of hydrogen fuel and its potential to replace conventional fuels. Hydrogen fuel does not emit CO2; it is a zero-emissions clean fuel that when consumed in a fuel cell leaves only water as a by-product.

While research methods of greenhouse gas to hydrogen conversion already exist, current techniques are often expensive and require the inclusion of rare metals and other elements, such as platinum and rhodium. However, the catalyst developed by the KAIST team is believed to be economically viable as it incorporates the cheap, abundant metal nickel into its structure.

Published in the journal Science, the researchers declare how their findings plot a possible route to a future of cheap and effective carbon reclamation.

We set out to develop an effective catalyst that can convert large amounts of the greenhouse gases carbon dioxide and methane without failure.

Cafer T. Yavuz, Co-author of the study and Associate Professor of Chemical and Biomolecular Engineering and Chemistry, KAIST

A Nickel for the Future

Throughout the development of the new catalyst, the scientists combined nickel-molybdenum nanoparticles with a crystalline magnesium oxide to increase the reaction rate. By sealing the nanoparticles in an oxygen free environment and exposing them to non-oxidizing gases the scientists discovered the process prevented a build-up of carbon. Furthermore, the nickel-based catalyst was able to function for over a month.

This process, known as dry reforming utilizes harmful gases including carbon dioxide and processes them to produce a synthesis gas. This residual gas product can then later be purified to produce hydrogen gas and other useful chemicals for fuel, plastic, and even pharmaceuticals. However, previous methods of this process were not cost-effective and often produced short-lived, inefficient reactions.

Yet, with nickel introduced into the process, costs are significantly reduced and the KAIST team has managed to circumnavigate the issue of a build-up of carbon byproducts that negatively distort the geometry and makeup of the catalyst. “The difficulty arises from the lack of control on scores of active sites over the bulky catalysts surfaces because any refinement procedures attempted also change the nature of the catalyst itself,” Yavuz said.

However, the introduction of the crystalline magnesium oxide changed the movement of the nanoparticles when heated under the reactive gases eliminating carbon build-up and producing an economical, efficient catalyst capable of recycling greenhouse gases. The combination of nickel, magnesium, and molybdenum could prove to be revolutionary in the global effort to slow down climate change and in the near-future reduce the burning of fossil fuels.

Solving the Challenges

Since the development of their unique catalyst, the researchers at KAIST noticed the magnesium oxide nanopowder derives from a form of magnesium oxide that is extremely fine in structure. Therefore, they have tagged their catalyst with the acronym NOSCE which stands for Nanocatalysts on Single Crystal Edges.

What’s more, because the surface of the catalyst displays no sign of defect all reactions can be predictable and consistently accurate, which was quite a surprise for the team.

It took us almost a year to understand the underlying mechanism. Once we studied all the chemical events in detail, we were shocked.

Youngdong Song, Lead author of the study and a Graduate Student in the Department of Chemical and Biomolecular Engineering, KAIST

Thus, the team believes they have solved several challenges for those working in the field of catalyst research and development. Their state-of-the-art catalyst conversion technique could improve other, “inefficient catalytic reactions,” he adds. Therefore, solving the challenges could now lead to further reducing greenhouse gas emissions and moving towards a future where carbon dioxide becomes a life-line in the fight against climate change rather than its death knell.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.