Apr 22 2020

Energy sources like solar and wind can efficiently generate emissions-free electricity, but they also rely on the Sun and the wind, respectively, and therefore supply does not invariably match the demand.

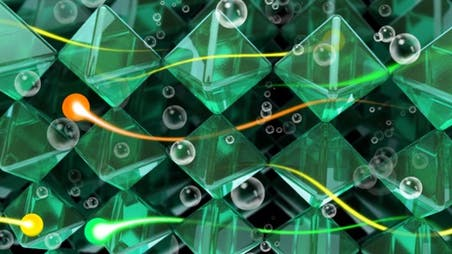

A new triple-conducting oxide allows protons, oxygen ions, and electrons to move through, allowing generation of either hydrogen or electricity through reversible operation in a protonic ceramic electrochemical cell. Image Credit: Idaho National Laboratory.

A new triple-conducting oxide allows protons, oxygen ions, and electrons to move through, allowing generation of either hydrogen or electricity through reversible operation in a protonic ceramic electrochemical cell. Image Credit: Idaho National Laboratory.

Similarly, nuclear power plants run more efficiently only at the highest capacity, which means the electricity generation cannot easily be boosted up or down based on the demand.

For many years, energy researchers have been attempting to overcome one major difficulty, that is, how to store surplus electricity, so that it can be released back onto the grid when required.

Now, scientists at Idaho National Laboratory have helped in resolving the difficulty by creating a novel electrode material for an electrochemical cell that is capable of changing surplus amounts of water and electricity into hydrogen, in an efficient way.

When there is a growing demand for electricity, the electrochemical cell undergoes a reversible operation and transforms the hydrogen back into electricity for the grid. The resultant hydrogen can also be utilized as fuel for vehicles, for heating purposes, or for other kinds of applications.

The study results were recently published online in the Nature Communications journal.

According to Dong Ding, a senior staff engineer/scientist and chemical processing group lead at Idaho National Laboratory, scientists had known for a long time that hydrogen is a potential energy storage medium.

The energy storage grand challenge, with its diverse research and development needs, gave rise to more opportunities for hydrogen. We are targeting hydrogen as the energy intermediate to efficiently store energy.

Dong Ding, Senior Staff Engineer/Scientist, Idaho National Laboratory

Along with his collaborators, Ding enhanced one type of electrochemical cell known as a protonic ceramic electrochemical cell, or PCEC for short, which utilizes electricity to divide steam into oxygen and hydrogen.

But in the earlier days, devices like these had certain limitations, particularly the fact that they only work at elevated temperatures of about 800 °C. Such high temperatures call for costly materials and lead to faster degradation, and thus render the electrochemical cells extremely costly.

In the study, Ding and his collaborators have explained a new kind of material— conductor—for the oxygen electrode. This conductor allows both oxygen reduction and water splitting reactions at the same time. This novel material—an oxide of a compound known as a perovskite—is different from many electrochemical cells and enables the cell to transform oxygen and hydrogen into electricity without surplus hydrogen.

Earlier, Ding and his collaborators created a three-dimensional (3D) mesh-like design for the electrode that resulted in the availability of more surface area to divide the water into oxygen and hydrogen. Collectively, both technologies—that is, the novel electrode material and the 3D mesh electrode—facilitated reversible, self-sustainable operation at temperatures ranging from 400 ºC to 600 ºC.

We demonstrated the feasibility of reversible operation of the PCEC at such low temperatures to convert generated hydrogen in hydrolysis mode to electricity, without any external hydrogen supply, in a self-sustaining operation. It’s a big step for high temperature electrolysis.

Dong Ding, Senior Staff Engineer/Scientist, Idaho National Laboratory

Although previous oxygen electrodes were able to conduct only oxygen ions and electrons, the novel perovskite is “triple conducting,” added Ding, implying that it conducts oxygen ions, electrons, and also protons. From a practical standpoint, the triple-conducting electrode suggests that the reaction occurs not only faster but also more efficiently; hence, the operating temperature can be decreased without affecting the excellent performance.

For Ding and his collaborators, the trick was to find out a method to introduce the element to the perovskite electrode material that would impart it with triple-conducting characteristics—a process known as doping.

We successfully demonstrated an effective doping strategy to develop a good triple-conducting oxide, which enables good cell performance at reduced temperatures.

Hanping Ding, Materials Scientist and Engineer, Chemical Processing Group, Idaho National Laboratory

In the days to come, Dong Ding and his collaborators are hoping to further enhance the electrochemical cell by integrating materials innovation with next-generation manufacturing processes so that the novel technology can be employed at a larger scale.