Reviewed by Alex SmithAug 25 2021

The growing potential of biomass as a source of sustainable, renewable and clean energy is gaining the focus of researchers.

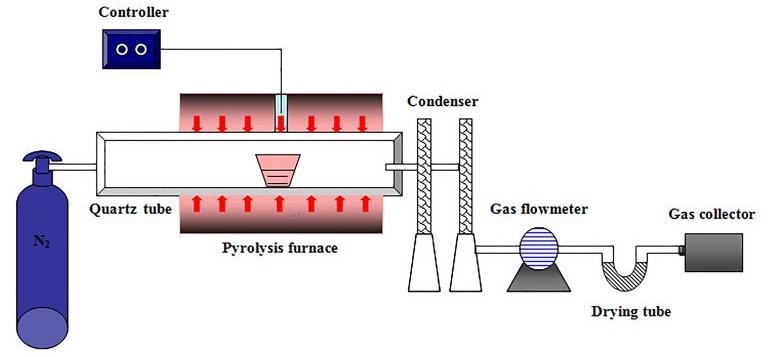

Tube furnace pyrolysis reactor. Image Credit: Aihui Chen, Xifeng Liu, Haibin Zhang, Hao Wu, Dong Xu, Bo Li, and Chenxi Zhao.

Tube furnace pyrolysis reactor. Image Credit: Aihui Chen, Xifeng Liu, Haibin Zhang, Hao Wu, Dong Xu, Bo Li, and Chenxi Zhao.

There is a possibility to convert biomass into bio-oil through thermochemical processes such as liquefaction, gasification and pyrolysis, which can then be used to produce chemicals, fuels and biomaterials.

Scientists from Heilongjiang Academy of Agricultural Machinery Sciences in China report their research on the physicochemical properties and antioxidant activity of wood vinegar and tar fraction in bio-oil produced from the pyrolysis hazelnut shells at 400 °C to 1,000 °C. The process has been reported in the Journal for Renewable and Sustainable Energy,

Wood vinegar is commonly used in agricultural fields as fertilizer, insect repellent and plant growth promoter or inhibitor. It can be also used as a wood preservative, odor remove, and animal feed additive.

After these results, wood vinegar and tar obtained from residual hazelnut shells could be considered as potential source of renewable energy dependent on their own characteristics.

Liu Xifeng, Study Author, Heilongjiang Academy of Agricultural Machinery Sciences, Harbin University of Science and Technology

The researchers discovered that after burning shells, the wood vinegar and tar residues comprised the most phenolic substances. This formed the base for further research on antioxidant properties.

The experiments were executed in a tube furnace pyrolysis reactor. The hazelnut shell samples weighing 20 g were placed in the waiting area of the quartz tube in advance. Once the target temperature was reached and was stabilized, the raw materials were pushed into the reaction region and heated for 20 minutes.

The biochar was quantified as the proportion of pyrolytic char to the biomass weight, while the bio-oil yield was measured by the increase in weight of the condenser.

The liquid product was centrifuged at 3200 revolutions per minute for 8 minutes to isolate two fractions of the bio-oil sufficiently. Here, the aqueous fraction was referred to as wood vinegar. The isolated tar fraction tends to remain stationary for a day with no sign of the aqueous phase.

The wood vinegar and tar were stored in a sealed tube and refrigerated at a temperature of 4 °C for further experimental purposes. The gas yield was measured by taking their combined volume into account.

The researchers observed that the pyrolysis temperature had a remarkable impact on the yield and characteristics of wood vinegar and tar fraction in bio-oil yielded from hazelnut shells. Wood vinegar formed the majority liquid fraction with the highest yield of 31.23 weight percent processed at 700 °C. This is attributable to the high concentration of water.

The study forms the base for more applications of bio-oil obtained from the pyrolysis of waste hazelnut shells. This also enhanced its application in antioxidant activity.

Journal Reference:

Chen, A., et al. (2021) Influence of pyrolysis temperature on bio-oil produced from hazelnut shells: Physico-chemical properties and antioxidant activity of wood vinegar and tar fraction. Journal of Renewable and Sustainable Energy. doi.org/10.1063/5.0051944.