As far as industries are concerned, acetone and isopropanol are crucial chemicals. They are utilized to produce materials collected from jet fuel to solvents to detergents to plastics.

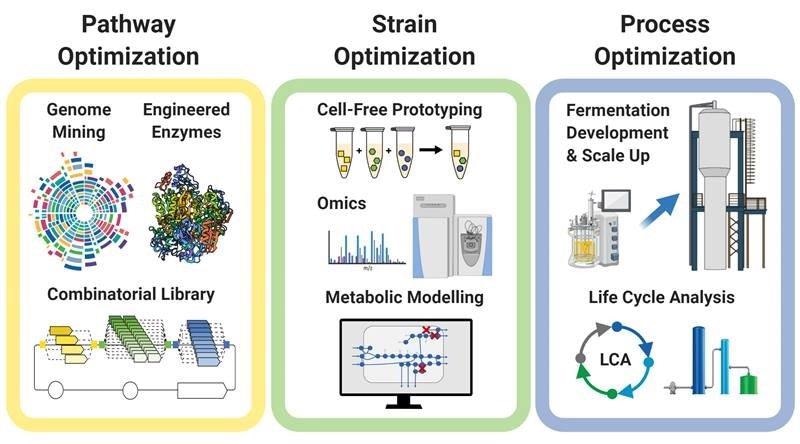

Schematic representation of the interdisciplinary approach used to develop a novel carbon-negative route for producing the commodity chemicals acetone and isopropanol, providing a blueprint for accelerated development of new biological processes. Image Credit: Liew, F., et al., (2022).

Schematic representation of the interdisciplinary approach used to develop a novel carbon-negative route for producing the commodity chemicals acetone and isopropanol, providing a blueprint for accelerated development of new biological processes. Image Credit: Liew, F., et al., (2022).

At present, these two chemicals are produced by the industry from petroleum via processes that release carbon dioxide and other greenhouse gases. Currently, scientists have come up with a new fermentation process that effectively transforms carbon oxide gases into isopropanol and acetone.

A combination of computer modeling, genomic analyses, and optimization of metabolic pathways have been utilized by scientists outside the cells to design bacterial strains. The result demonstrate that bacteria can help transform carbon waste into useful materials.

The Impact

A new process has been developed by the researchers to transform agricultural, industrial and urban waste gases into significant chemicals. This process tends to capture more carbon gases compared to what it releases. Researchers term this “carbon-negative” biomanufacturing.

The new approach enables the industry to produce fuels, plastics and other chemicals in a highly sustainable manner. Also, this method will result in the quicker development of effective cell-based production techniques. This will decrease the greenhouse gas emissions and other environmental effects of industrial activity.

Summary

Scientists from Oak Ridge National Laboratory, LanzaTech Inc., Northwestern University, and the University of Tennessee utilized an interdisciplinary method to improve strains of the bacterium Clostridium autoethanogenum to improve the production of isopropanol and acetone from waste gases.

Initially, the researchers searched the genomes of a collection of industrial strains for enzymes that tend to produce isopropanol and acetone. They tested several combinations of those enzymes in these bacteria to choose the highly efficient engineered sets of enzymes.

Furthermore, the researchers further enhanced those metabolic pathways with the help of computational modeling, proteomic analyses and cell-free enzyme screenings to determine competing pathways and metabolic bottlenecks.

The researchers then adapted the process for high rates and stability and scaled up cultures up to 120 L for the constant transformation of waste gas to isopropanol or acetone.

Employing a life cycle analysis, the researchers illustrated that this biomanufacturing method decreased emissions of greenhouse gas by 165% in comparison to fossil fuel-based processes.

This biological process captures carbon while the production of these two chemicals from fossil fuels liberates carbon gases. Such outcomes display that engineered acetogenic bacteria allows viable, high-efficiency, and high-selectivity chemical production.

This multifaceted strain and process optimization illustrate the ability of continued advances in biotechnology to move industrial practices toward more sustainable methods.

The study was financially supported by the Department of Energy (DOE) Office of Science’s Biological and Environmental Research program and the Office of Energy Efficiency and Renewable Energy’s Bioenergy Technologies Office.

DNA synthesis was offered by the DOE Joint Genome Institute’s Community Science Program. Also, the authors acknowledge assistance from LanzaTech’s private investors.

Journal Reference:

Eric, L. F., et al. (2022) Carbon-negative production of acetone and isopropanol by gas fermentation at industrial pilot scale. Nature Biotechnology. doi.org/10.1038/s41587-021-01195-w.