The new regulatory framework (Energy Efficiency eXisting ship Index - EEXI) around CO2 emissions for existing shipping come into force in January 2023 and many ship owners are now considering how to meet these through either operational changes or technical alterations.

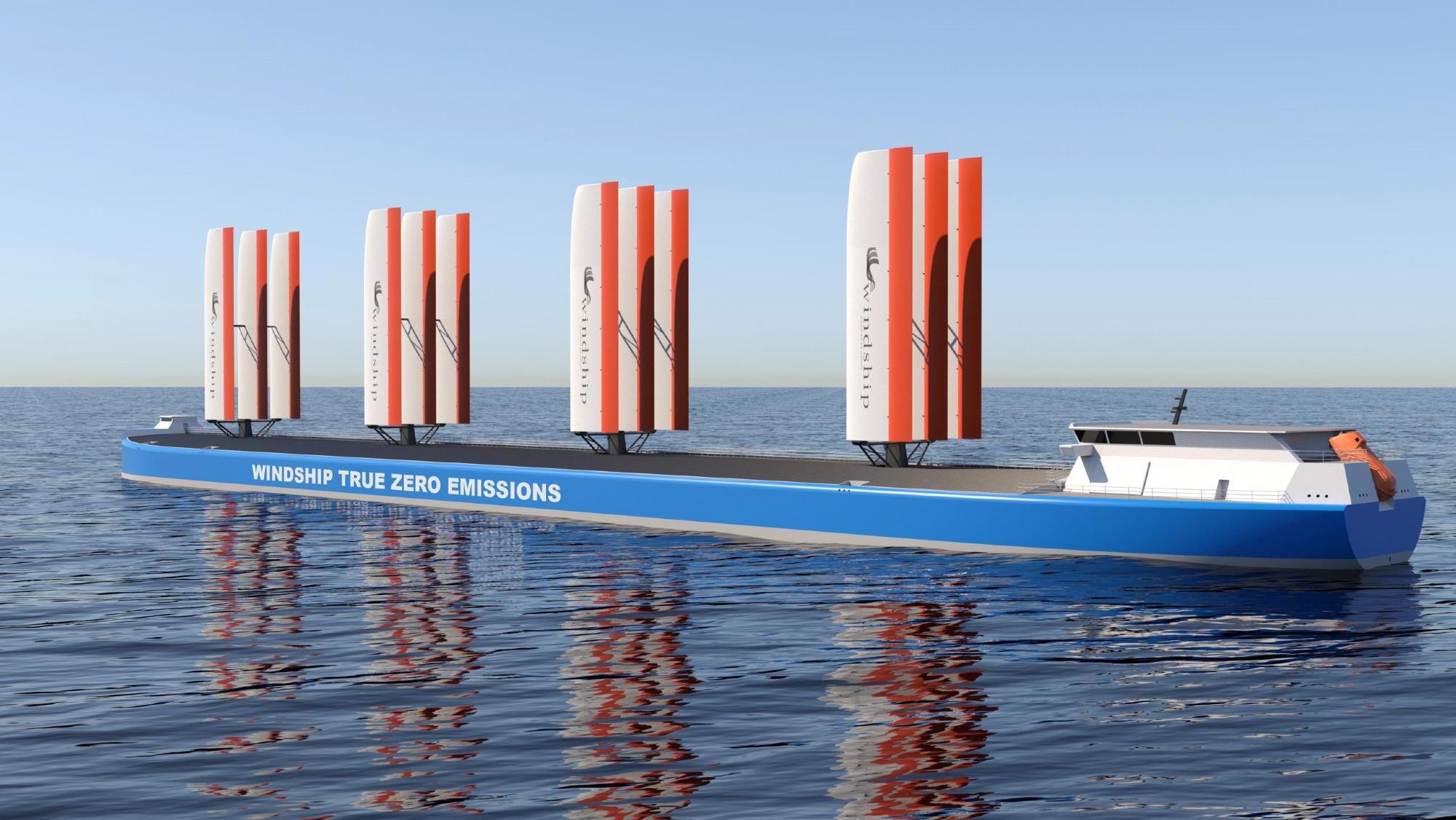

Image Credit: Windship Technology Ltd

Windship Technology today publishes proprietary research that allows ship operators, owners and charterers the ability to easily see the positive, game-changing operational effect that installing just one 36m rig can have on their vessel going forward.

These regulations seek to measure the efficiency of ships through the amount of CO2 emitted per tonne per mile of freight carried in a year. Ships will be rated annually, from A, the highest performing, to E the lowest and the results will be recorded in the Ship Energy Efficiency Management Plan (SEEMP). Ships rated D for three consecutive years or E for a single year need to develop an approved corrective action plan as part of the SEEMP.

The International Maritime Organisation (IMO) have currently set a 2% reduction per year on Carbon Intensity Index (CII) requirements until 2025, at which point the reduction will need to increase to get towards the overall IMO CO2 reduction goals of 2050.

Wärtsilä have reported the results of their CII Insight tool, which has predicted that when CII comes into force, about 45% of the fleet is forecast to be in category D, with a further 16% in category E. They further predict that, if nothing is done and assuming the IMO trajectory stays constant, by 2030, 81% of the bulker fleet, 57% of tankers and 80% of container ships will be in category E.

The most common approach to achieving compliance as of 2023 is to reduce the speed of the vessel through engine power limitation (EPL), which will reduce the amount of fuel per tonne per mile used, as ship resistance is proportional to the cube of the speed of the vessel. For some vessels this will be a short-term solution, for others the EPL required maybe significant, potentially meaning the engine will be operating well outside of its ideal parameters.

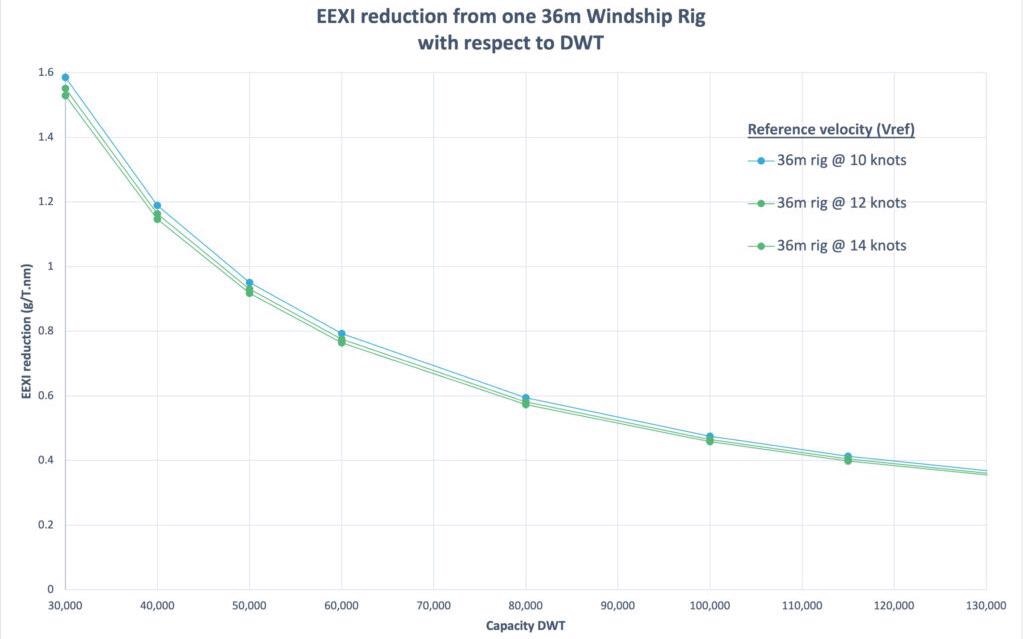

Apart from operational changes such as EPL, owners can implement technical efficiency improvements, and it’s here where the obvious installion of Windship Technology’s patented, high-performing rigs are most efficient. The performance of the Windship 36m rig has been calculated using computational fluid dynamics (CFD). This performance data can then be combined with the EEXI wind matrix to enable the reduction in EEXI for a given vessel to be assessed.

Windship Technology have conducted this assessment for a range of vessel DWT (Deadweight tonnage) to provide owners with a guide as to the powerful effect a single 36m rig could have on their ship. This technology can be used in conjunction with EPL if required to achieve compliance. A further benefit of this approach would be to consider adding a second rig, if in due course the CII required further reductions. Clearly the final EEXI reduction will be dependent on actual ship performance characteristics, however the graph provides a good indication of the potential.

Simon Rogers, Technical Director of Windship Technology is clear about the benefits: “This is a known issue that is fast coming down the track and one that ship operators must start addressing. What we have developed with our patented, high power rig design is a solution that works in tandem with existing EPL measures but greatly enhances performance. Our assessment is an EPL reduction of some 20-25% depending on the size of the vessel and not only are we extending the operational life of the ships that install Windship Technology rigs but we are making global shipping compliant and faster.”

Graham Harvey, Chief Executive of Windship Technology further added: “It’s very clear from the chart below the positive effects that installing our patented rigs has on performance. Owners, Operators and Charterers are all highly aware of the regulatory framework that is close to being imposed by the IMO and time is running out to achieve compliance. We are hosting a broad range of discussions with key players in the industry now and it’s very clear that Windship Technology is very much part of the solution going forward. We welcome further enquiries and discussion from interested parties.”

Image Credit: Windship Technology Ltd