Carbon dioxide must not be discharged into the atmosphere to safeguard the climate. Wherever CO2 generation cannot be controlled, it should be collected and transformed into other materials.

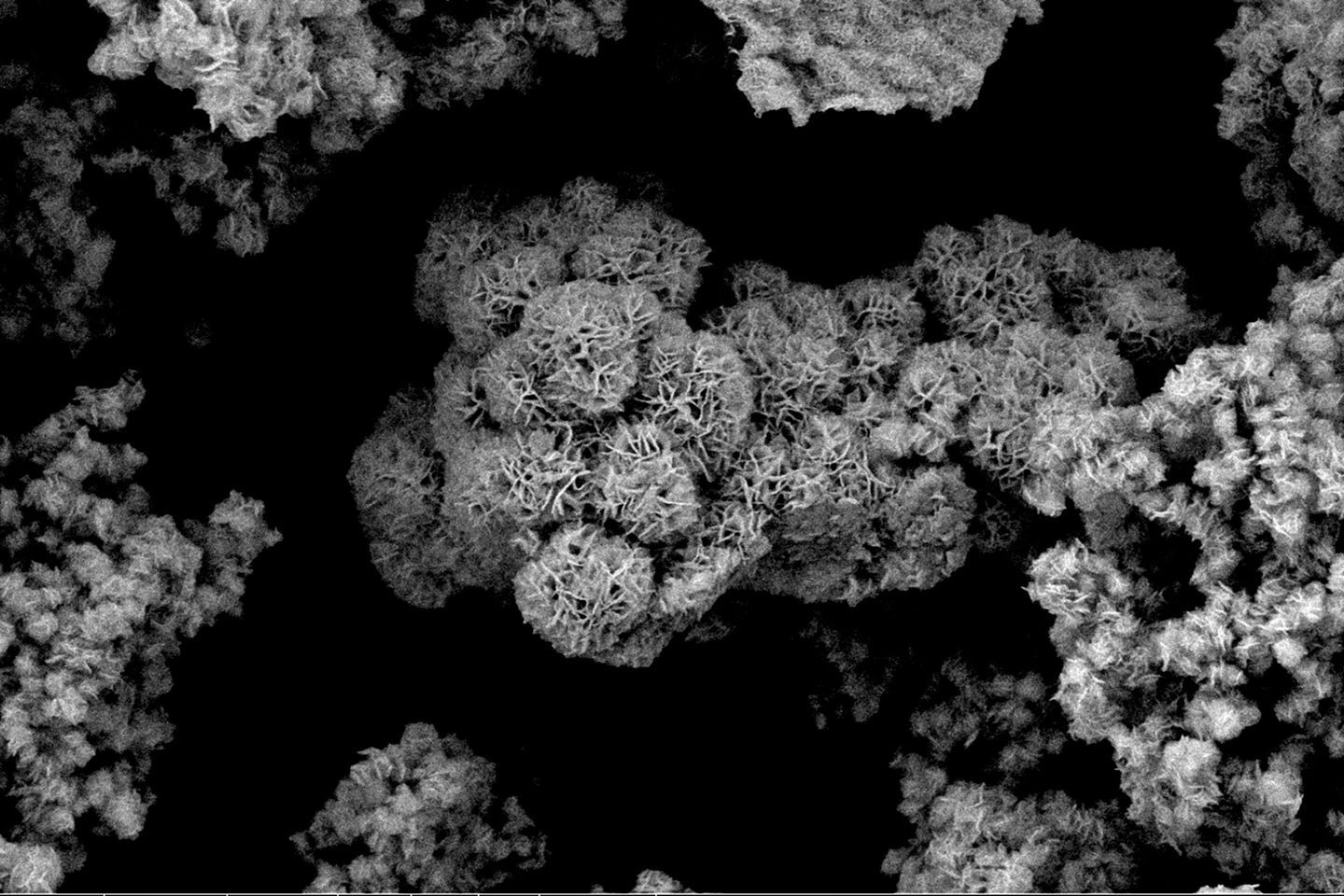

Molybdenum disulfide under the scanning electron microscope. Image Credit: TU Wien

Molybdenum disulfide under the scanning electron microscope. Image Credit: TU Wien

Making valuable, marketable compounds is the best solution. A novel technique for doing this has now been created at TU Wien (Vienna). Liquid methanol is formed from CO2 with the aid of a unique catalyst material consisting of sulfur and molybdenum.

The new technology has already been patented, and now it has to be ramped up to industrial size in collaboration with business partners.

Profit from Waste Gas

The most effective place to use carbon dioxide is just where it is most concentrated, for instance, in the exhaust gas stream of big industrial facilities. It is not a novel concept to turn CO2 into useful items. However, it is a challenging and intricate process. Sometimes it is necessary to enrich and separate CO2 first, adding to the expenses and energy input.

To convert carbon dioxide, catalysts based on copper have often been used so far. However, they have the major disadvantage that they are not robust. If there are certain other substances in the exhaust gas stream besides carbon dioxide, for example sulfur, the catalyst quickly loses its activity. It is said that the catalyst is poisoned.

Prof. Karin Föttinger, Institute of Materials Chemistry, TU Wien

Therefore, Karin Föttinger and her study team set out to locate a better resource.

Föttinger added, “If you want to use such methods not only in the laboratory but also on a large scale in industry, then you need a catalyst that is perhaps a little less active, but robust, durable, and reliable. You want to be able to process quite ordinary industrial waste gases without pre-treatment.”

The Winning Formula: Sulfur and Molybdenum

The research team from TU Wien was able to demonstrate that sulfur and molybdenum-based catalysts meet these criteria. The activation and conversion of CO2, which is actually quite inert, are ensured by special supplementary elements like manganese.

The qualities of the catalysts can be carefully tailored to the intended region of application by selecting such additional ingredients. In this manner, CO2-containing waste gas may now be converted into methanol.

“Methanol is an attractive product. It is liquid at room temperature, so it can be stored without any problems. It is needed in industry; up to now it has normally been produced from fossil raw materials. But it is also possible to use our catalysts to produce other molecules, such as higher alcohols. We are currently still working on figuring out exactly how best to choose parameters like pressure and temperature to produce different products,” Föttinger added.

The technique has now been patented, and in cooperation with partner businesses, it will now be scaled up to an industrial level.

Föttinger stated, “We are already working with companies, and at the same time we are looking for other possible collaborations.”

The development of innovative catalysts should help the sector become climate neutral and close material cycles.

The Research and Transfer Support of TU Wien provided funding to support the patenting.

The study is being conducted as a part of the doctoral college “CO2 Refinery,” which at TU Wien is creating novel, multidisciplinary techniques for the ecologically sustainable use of CO2.