Scientists are attempting to overcome some of the major constraints of existing lithium-ion battery technology, which employs a graphite anode and a lithium-based transition metal oxide cathode, as electric vehicles and personal portable gadgets grow more prevalent.

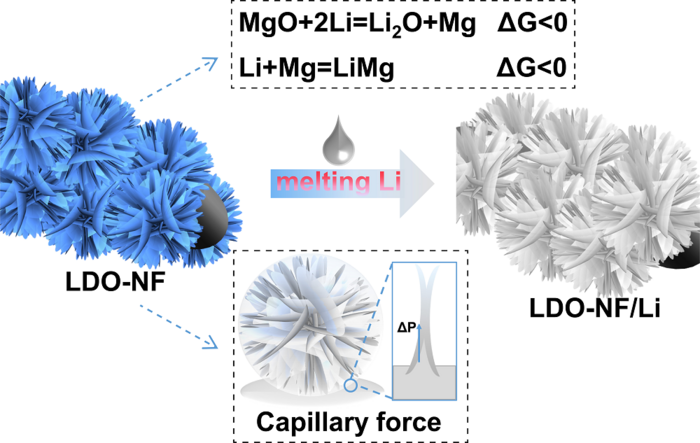

Interfacial reaction driving force together with capillary force facilitate the transient infiltration of molten Li into a 3D host for stable 3D composite lithium anode. Image Credit: Nano Research, Tsinghua University Press.

Alternatively, lithium metal batteries, which use a lithium anode in addition to a lithium cathode, might have the ability to alleviate some of these issues, resulting in high-energy, long-lasting, and relatively safe lithium-ion battery alternatives.

Two significant obstacles need to be overcome for the widespread use of lithium metal batteries. The first is that lithium dendrites, which are metallic deposits, tend to accumulate in these batteries. The second issue is that these batteries have considerable differences in electrode volume. Both issues result in decreased performance and increased safety risks.

Researchers came up with a technique for producing a three-dimensional composite lithium anode employing thermal infusion which successfully tackles lithium deposition and energy loss during charge cycles. The study was published on October 11th, 2022, in the journal Nano Research.

Lithium metal batteries emerge as the promising electrochemical storage devices for electric vehicles due to their high energy density; however, these issues related to the growth of lithium dendrites and large electrode volume variations of lithium anode restrict their practical application. It is highly desirable to explore suitable ways to address the issues of lithium anodes so these batteries can become a more practical option.

Feifei Cao, Researcher, Huazhong Agricultural University

Scientists developed a 3D scaffold and infused molten lithium onto it to produce a lithium metal battery that overcomes these issues. The use of a layer of magnesium–aluminum double-oxide nanosheets is essential to guarantee the safety of this approach. This substance is referred to as lithiophilic, which simply implies that it draws lithium to produce an alloyed medium.

Lithium that is in a molten state is drawn to the nanosheets and then transported through the 3D scaffold via capillary action. According to Cao, this capillary force is crucial because it makes it possible for molten lithium to briefly infiltrate the 3D host and produce a stable 3D composite lithium anode.

The batteries created using the novel approach were subjected to rigorous testing by the investigators. When compared to conventional technology, the batteries generated tubular dendrites with only a 3% thickness variation. In comparison, the huge electrode increased by 22% without the innovative method.

The researchers also examined the battery’s coulombic efficiency, or current efficiency, which assesses the capacity and energy loss of the battery. The battery’s efficacy remained at 98.6% after 100 charging cycles. In comparison, the standard lithium metal batteries experienced massive energy loss only after 23 charge cycles.

Scientists are focusing on ways to enhance lithium metal batteries so that this technology can be more extensively used.

For the next step, we will replace the heavy matrix with a light-weight matrix to yield a high weight ratio of active lithium to improve the battery energy density. We expect to prepare a high safety composite lithium anode that is competitive for high gravimetric energy-density cell with more than 500 Wh kg-1.

Feifei Cao, Researcher, Huazhong Agricultural University

Lan-Xing Li, Yun-Nuo Li, and Huan Ye of Huazhong Agricultural University’s College of Science also contributed to the study.

The study was supported by the National Natural Science Foundation of China (Grant Nos. 21975091, 21805105, and 21773078), the Natural Science Foundation of Hubei Province (Program No. 2019CFA046), and the Fundamental Research Funds for the Central Universities of China (Grant No. 2662021JC004).

Journal Reference

Li, L.-X., et al. (2022) Lithiophilic interface guided transient infiltration of molten lithium for stable 3D composite lithium anodes. Nano Research. doi.org/10.1007/s12274-022-4981-3.