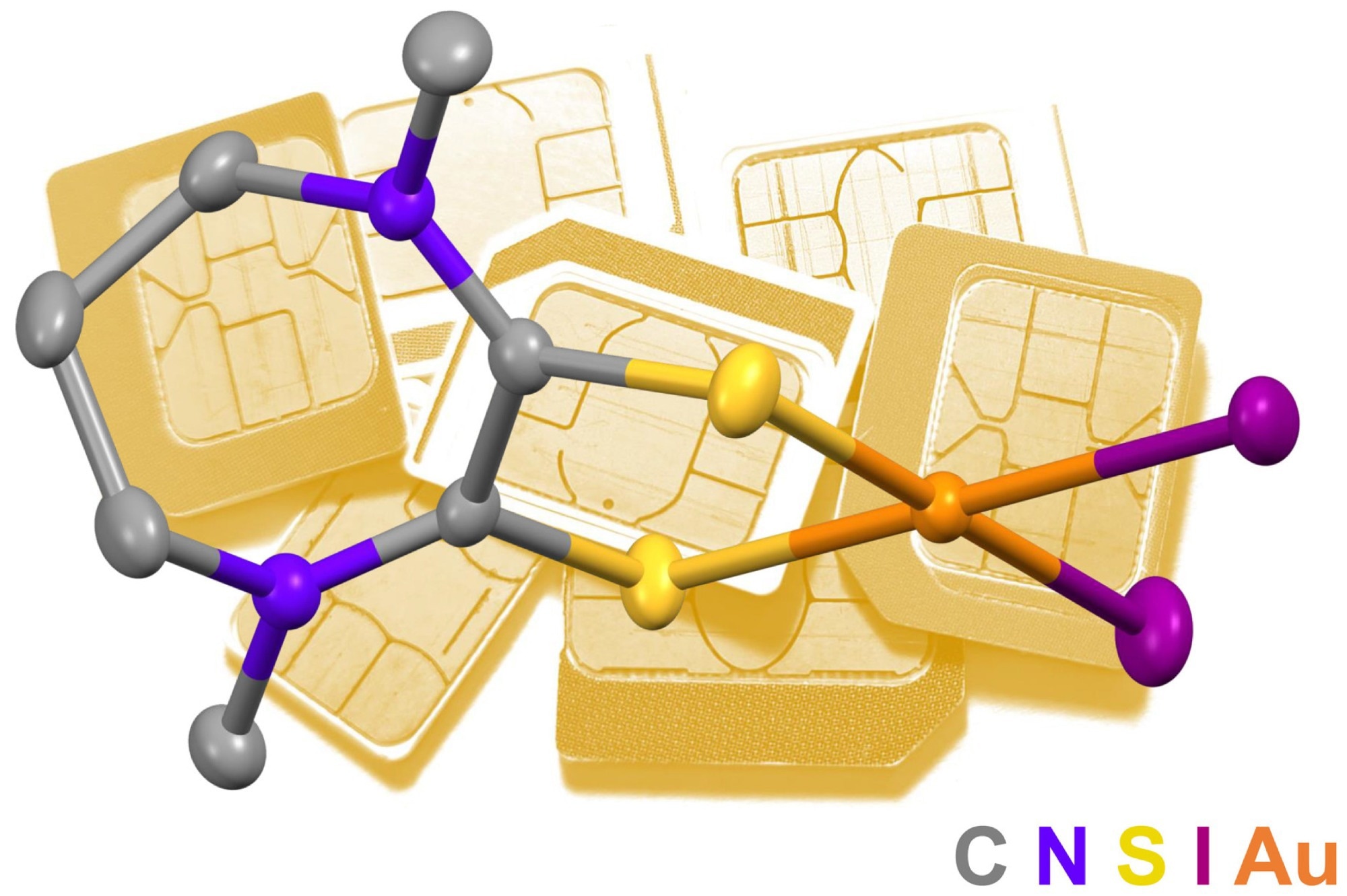

Scientists have made use of gold that has been extracted from electronic waste as catalysts for reactions that could be employed in medicine making.

Image Credit: Imperial College London

Using the gold from electronic waste again avoids it from being lost in a landfill, and making use of this retrieved gold for drug manufacture decreases the necessity to mine new materials. Often, catalysts are made of rare metals, which are extracted with the help of costly and detrimental mining processes.

The technique utilized for withdrawing gold was developed by scientists at the University of Cagliari in Italy, and the process for making use of the recovered gold was developed by scientists at Imperial College London.

The study has been reported in the journal ACS Sustainable Chemistry & Engineering.

Normally, waste electrical and electronic equipment (WEEE) is sent to a landfill, as isolating and extracting the components needs lots of energy and hard chemicals, thereby undermining its economic viability. However, WEEE consists of a wealth of metals that can be utilized in a range of new products.

Determining methods to recover and use such metals in an affordable, low-energy, and non-toxic way is hence vital for making the use of electronic goods highly sustainable.

Resource, Not Waste

It is shocking that most of our electronic waste goes to landfill and this is the opposite of what we should be doing to curate our precious elemental resources.

James Wilton-Ely, Study Lead Researcher and Professor, Department of Chemistry, Imperial College London

Wilton-Ely continued, “Our approach aims to reduce the waste already within our communities and make it a valuable resource for new catalysts, thereby also reducing our dependence on environmentally damaging mining practices.”

“We are currently paying to get rid of electronic waste, but processes like ours can help reframe this ‘waste’ as a resource. Even SIM cards, which we routinely discard, have a value and can be used to reduce reliance on mining and this approach has the potential to improve the sustainability of processes such as drug manufacture,” added Wilton-Ely.

Professors Angela Serpe and Paola Deplano, from the University of Cagliari, came up with an affordable method to withdraw gold and other valued metals from electronic waste like SIM cards, printed circuit boards (PCBs), and printer cartridges under mild conditions.

This patented process includes selective steps for the tenable leaching and recovery of base metals like nickel, then silver, copper, and, eventually, gold. This is performed using green and safe reagents.

But the gold generated from this process comes under the part of a molecular compound and hence cannot be re-used again for electronics in the absence of investing a lot more energy to achieve the gold medal.

Searching for use in this compound of recovered gold, the team of Professor Wilton-Ely and his colleague, Professor Chris Braddock, examined if it could be employed as a catalyst in the manufacture of beneficial compounds, such as pharmaceutical intermediates.

Sustainable Catalysts

Catalysts are utilized to increase the rate of a chemical reaction while staying unaltered and are utilized in the majority of processes to produce materials. The research team tested the gold compound in various reactions that have been generally utilized in pharmaceutical manufacture, for instance, in making pain relief and anti-inflammatory drugs.

The researchers discovered that the gold compound provided good performance or better compared to the catalysts utilized at present, and is also reusable.

The scientists indicate that making it economically feasible to retrieve gold from electronic waste could make spin-off uses for other components that have been recovered in the process. For instance, in the process, nickel and copper are also leached out, as is the plastic itself, with all these components able to be utilized in new products.

By weight, a computer contains far more precious metals than mined ore, providing a concentrated source of these metals in an ‘urban mine’.

Sean McCarthy, PhD Student and Research Lead, Imperial College London

Professor Serpe stated, “Research like ours aims to contribute to the cost-effective and sustainable recovery of metals by building a bridge between the supply of precious metals from scrap and industrial demand, bypassing the use of virgin raw materials.”

The teams are completely focused on extending this method to the recovery and re-use of palladium content in end-of-life automotive catalytic converters. This is especially crucial as palladium has been extensively utilized in catalysis and is highly affordable compared to gold.

Journal Reference:

McCarthy, S., et al. (2022) Homogeneous Gold Catalysis Using Complexes Recovered from Waste Electronic Equipment. ACS Sustainable Chemistry & Engineering. doi.org/10.1021/acssuschemeng.2c04092.