The quest for alternative clean and renewable energy solutions has never been more pressing due to the environmental and energy problems caused by fossil fuels. Among these, hydrogen (H2) is recognized as a powerful contender in the energy sector, with applications in both stationary and mobile settings.

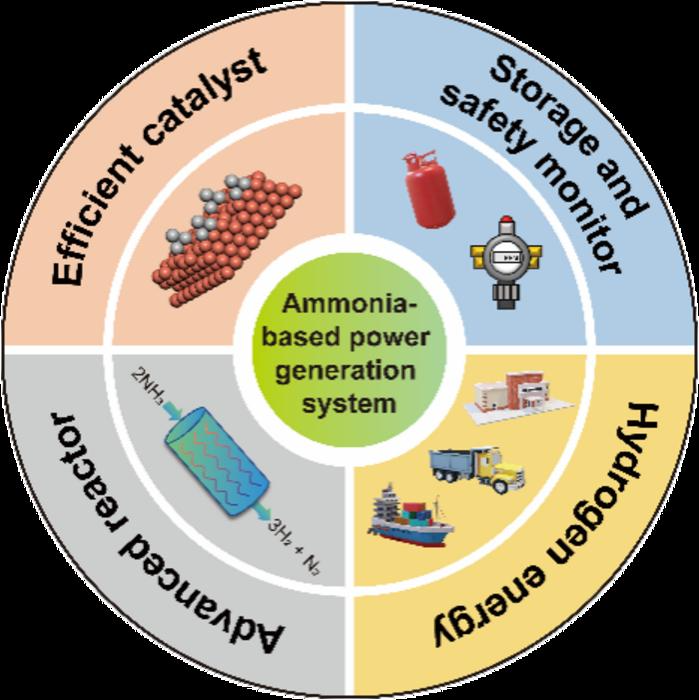

The potential of utilizing ammonia as a hydrogen carrier for on-site power generation via ammonia decomposition is systematically discussed. Image Credit: Zhonghua Xiang, Beijing University of Chemical Technology

However, the commercialization of hydrogen fuel cells is hampered by the difficulties associated with handling and transporting hydrogen due to its low volumetric energy density.

Fortunately, owing to its high hydrogen content (17.6 wt%) and prospective economic benefits for energy production, ammonia (NH3) is regarded as a promising hydrogen carrier. It produces only nitrogen and water as byproducts when burned as a fuel, making it a carbon-free alternative to conventional fossil fuels.

It can liquefy at 0.86 MPa at 25 °C, resulting in a high volumetric energy density of 10.5 MJ L-1, which is twice that of compressed hydrogen at 70 MPa (5 MJ L-1). A group of scientists thoroughly debated the feasibility of using ammonia as a hydrogen carrier for on-site power generation via ammonia decomposition. The study was published in the Industrial Chemistry & Materials journal.

There has been growing interest in the utilization of ammonia as an energy vector. In this perspective, we addressed the chemical properties along with recent projects or worldwide chemical plants. Furthermore, we discussed the design strategies of catalysts and reactors, as well as their benefits and drawbacks. We hope this perspective could shed light on the potential of ammonia as a promising alternative to traditional hydrogen storage methods and highlights the challenges and opportunities that lie ahead in this exciting field of research.

Zhonghua Xiang, Professor, Beijing University of Chemical Technology

Storing renewable energy in the form of chemical fuels is regarded as a practical approach for both short- and long-term storage, particularly in the transportation sector. Because of its advantageous chemical properties, NH3 has been proposed as a more technically feasible option than CH3OH in this regard.

NH3 has a 40% higher gravimetric H2 content than CH3OH while retaining a comparable volumetric energy density. Acquiring pure carbon dioxide streams from industrial emissions is not a viable long-term solution for carbon-based fuels, and the cost of directly capturing carbon dioxide from the air is high.

One of the primary limitations of ammonia is its apparent toxicity, which is approximately three orders of magnitude greater than that of methanol or gasoline. To ensure safe use, recommended exposure limits for NH3 are set below 100 ppm.

Zhonghua Xiang, Professor, Beijing University of Chemical Technology

“However, it is possible to monitor potential NH3 leaks and hazards in real-time using appropriate sensors. Furthermore, the human nose can detect ammonia at concentrations as low as 5 ppm in air, making it much more noticeable than odorless hydrogen. Therefore, it is practical to carry out appropriate hazard management to effectively mitigate the risk of ammonia exposure to both humans and the environment,” Xiang adds.

The application of ammonia for power generation systems can be either stationary or portable, making it even more attractive. In China, Jiang's team from Fuzhou University developed a demonstration project that utilizes ammonia for on-site hydrogen production at a hydrogen fueling station, aiming to create a zero-carbon-emission energy community.

Dr. Lingling Zhai, Researcher, Beijing University of Chemical Technology

“Currently, the American technology startup company, Amogy, is launching testing operations for a 200 kW tugboat for maritime applications in cooperation with the Sustainable Energy Catapult Center in Norway. International organizations such as the Ammonia Energy Association (AEA), the International Renewable Energy Agency (IRENA), and the Oxford Institute for Energy Studies (OIES) have also made significant efforts to promote the application of ammonia as a sustainable energy commodity,” Zhai stated.

Several factors should be considered when implementing ammonia-based power generation systems: 1. To avoid ammonia leakage, the storage tank and all connected components should be made of anti-corrosion materials. 2. Ammonia decomposition catalysts with low temperatures (<450 °C) and reactors with high volumetric energy densities are essential. 3. Policies and regulations that encourage the use of renewable energy sources can help speed up the transition to a low-carbon economy.

“With the context of the above discussions, we expect an ‘ammonia to hydrogen’ economy may ease the scalable use of green hydrogen in the foreseeable future,” Xiang concluded.

Journal Reference

Zhai, L., et al. (2023). Ammonia as a carbon-free hydrogen carrier for fuel cells: a perspective. Industrial Chemistry & Materials. doi.org/10.1039/D3IM00036B.