Alkylamines are multipurpose chemicals that can do everything from improving the effectiveness of herbicides to easing allergy problems. Unfortunately, hazardous waste byproducts are produced during standard alkylamine production processes. Thus, a sustainable and economical technique of manufacturing alkylamines has been actively sought after.

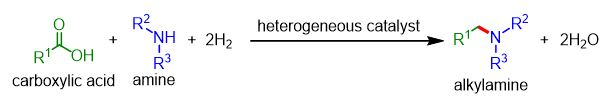

Reductive amination of carboxylic acids. Image Credit: Osaka University

Reductive amination of carboxylic acids. Image Credit: Osaka University

Now, an Osaka University-led research team has discovered a method in a study that was just published in Green Chemistry. The group has created a mildly effective alkylamine synthesis technique that yields just water as a byproduct. It is hoped that the simple, eco-friendly reaction conditions described here will encourage improvements in other common chemical syntheses used in industry.

Alkylamines are used in the production of numerous daily products, including furniture and sports apparel. Thus, how are these amazing molecules produced? Since carboxylic acids can be obtained sustainably, for example from biomass, they are a great place to start. But the present synthetic processes also generate a lot of waste or need reaction settings that are challenging to experiment with, including high temperatures and pressures.

Thus, while producing alkylamines, the industry normally stays away from using carboxylic acids as a starting material. The research team set out to create a novel synthetic procedure that functions at temperatures and pressures that are practical for experiments.

In our work, we unveil a novel catalyst system, a platinum – molybdenum catalyst, that can transform carboxylic acids into amines. This produces alkylamines, which can be used for surfactants, pharmaceuticals and more.

Katsumasa Sakoda, Study Lead Author, Osaka University

The synthetic methodology developed by the researchers has various advantages: For starters, the reaction conditions are gentle, needing just atmospheric hydrogen pressure and temperatures of up to 160 °C. At 363, the turnover number, or the number of moles of substrate that a mole of catalyst can convert, is large.

The catalyst is recyclable at least five times. Many carboxylic acid and amine starting materials are compatible with the reactions under consideration, such as the conversion of fatty acids to fatty amines. The reaction yields are high - up to 99%, with just water as a byproduct.

We are excited because our research improves the environmental sustainability and simplifies the experimental setup of a common class of chemical syntheses. We hope that this is only the first step toward the development of greener catalyst processes.

Tomoo Mizugaki, Study Senior Author, Osaka University

The efforts of the team have made significant progress toward improving the sustainability of a chemical process needed to synthesize several common goods. The experimental synthesis methods are easily adaptable to different catalytic processes due to their safety and simplicity.

Journal Reference:

Sakoda, K., et. al. (2023) Reductive amination of carboxylic acids under H2 using a heterogeneous Pt–Mo catalyst. Green Chemistry. doi:10.1039/D3GC02155F