Researchers at Delft University of Technology (TU Delft) in The Netherlands have made significant progress toward sustainable industrial fermentation by revealing ground-breaking developments in the purification of acetone and isopropanol from waste gas fermentation.

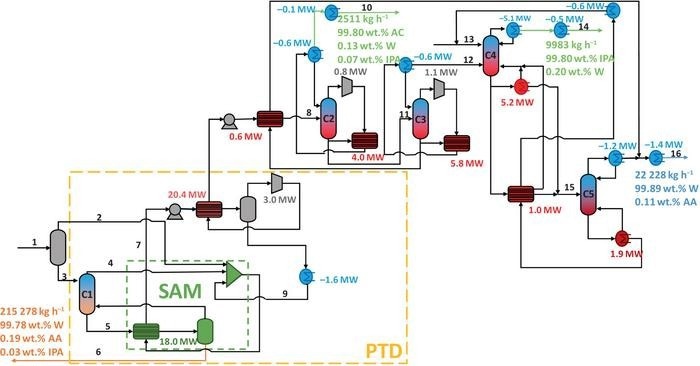

Flowsheet of isopropanol and acetone recovery process using vacuum distillation (VD) process configuration (W - water, IPA - isopropanol, AC - acetone, AA - acetic acid). Image Credit: Anton A Kiss

The study, which was published in the Journal of Chemical Technology and Biotechnology at SCI, presents new techniques that could improve large-scale production's viability and efficiency.

The combined global market for acetone and isopropanol is $10 billion. Both substances are crucial industrial solvents, and because of their low toxicity, isopropanol finds extensive use as a medicinal ingredient. Conventional production depends on carbon-dependent fossil fuels, which are less advantageous as environmental rules tighten.

Overturning Conventional Production

Using engineered bacteria to recycle industrial waste gases and syngas a combination of carbon monoxide and hydrogen that can be created from bio-waste is a promising and environmentally friendly manufacturing process. Notably, this syngas fermentation process is presently being piloted by LanzaTech, a US-based biotechnology business unrelated to TU Delft's research, to create acetone and isopropanol.

Due to low product concentrations from the fermentation process, which produce a very diluted fermentation broth, there may be a hurdle to scaling up this technology at the product purification step.

The challenge is to remove a large amount of water per kilogram of product, without high energy costs. This was addressed in our research by determining the optimal operating conditions that allowed significant process heat recovery.

Anton A. Kiss, Professor and Study Corresponding Author, Department of Chemical Engineering and Biotechnology, Delft University of Technology

Highly Efficient Downstream Processes

The group concentrated on two methods: vacuum distillation and pass-through distillation, for the initial recovery of acetone and isopropanol.

Vacuum distillation was investigated as a classic method that can be used for recovery of volatile fermentation products, while pass-through distillation is a novel separation method that has never been implemented to complex mixtures.

Anton A. Kiss, Professor and Study Corresponding Author, Department of Chemical Engineering and Biotechnology, Delft University of Technology

He pointed out that vacuum distillation requires costly refrigeration, which is not necessary with the pass-through distillation method.

With recoveries of more than 99.2%, high-purity isopropanol and acetone were produced by successfully designing industrial-scale procedures. According to the research, all of the suggested procedures are quite competitive in terms of cost and environmental effects. When thinking about incorporating these procedures into manufacturing facilities

Kiss said, “Due to possible differences in availability of electricity and heating utilities, the optimal process design should be chosen depending on the exact plant location.”

Paving the Way for Sustainable Industrial Fermentation

This study's innovative methods for recovering acetone and isopropanol represent a major advancement in industrial fermentation that is sustainable. The group is currently focusing on other valuable substances that need to be purified.

We are designing recovery processes for various volatile chemicals from fermentation broth, to find general design rules. We are working on collaborations in which we can transfer our knowledge to companies who can implement these designs in industry.

Anton A. Kiss, Professor and Study Corresponding Author, Department of Chemical Engineering and Biotechnology, Delft University of Technology

Journal Reference

Janković, T., et.al., (2023). Advanced purification of isopropanol and acetone from syngas fermentation. Journal of Chemical Technology and Biotechnology. doi.org/10.1002/jctb.7576.