Nov 16 2008

In future, polymethyl methacrylate (PMMA for short) – better known as acrylic glass – could be made from natural raw materials such as sugars, alcohols or fatty acids. PMMA is manufactured by polymerising methyl methacrylate (MMA).

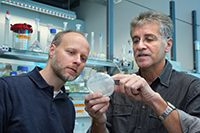

Microbiologists Dr. Thore Rohwerder (left) from the University of Duisburg-Essen and his mentor Dr. Roland Müller (right) from the Helmholtz Centre for Environmental Research (UFZ) in the laboratory. Photo: Klaus-D. Sonntag/fotoplusdesign

Microbiologists Dr. Thore Rohwerder (left) from the University of Duisburg-Essen and his mentor Dr. Roland Müller (right) from the Helmholtz Centre for Environmental Research (UFZ) in the laboratory. Photo: Klaus-D. Sonntag/fotoplusdesign

In a bacterial strain, scientists at the University of Duisburg-Essen and the Helmholtz Centre for Environmental Research (UFZ) have found an enzyme which could be used for the biotechnological production of a precursor of MMA. Compared with the previous chemical production process, a biotechnological process is far more environmentally friendly.

Dr Thore Rohwerder has been nominated as one of three candidates for the European Evonik research award for his discovery. The competition is overseen by Dr Arend Oetker, president of the Stifterverband für die Deutsche Wissenschaft (Association of Donors to German Science). The aim of the award is to encourage young researchers to risk taking the step from the laboratory into business. The topic of the 2008 Evonik research award is "White Biotechnology" (industrial biotechnology). The Science-to-Business Award worth EUR 100,000 was given to Dr. Paul Dalby from the University College London on November 12th in Berlin. Dalby’s method for combining enzymes and customizing them for new tasks convinced the international jury.

The newly enzyme discovered by Dr. Thore Rohwerder und Dr. Roland H. Müller, called 2-hydroxyisobutyryl-CoA mutase, makes it possible to turn a linear C4 carbon structure into a branched one. Compounds of this type are precursors of MMA. Parent compounds may of course include intermediate products from the petrochemical industry. The revolutionary aspect, however, is that this enzyme, integrated into metabolically appropriate microorganisms, can also transform sugars and other natural compounds into the products desired. Until now, the only way to produce this precursor – 2-hydroxyisobutyrate (2-HIBA) – was a purely chemical process based on petrochemical raw materials. The chemicals industry worldwide is searching for suitable biological processes, so that in future, renewable raw materials can also be used as a basis for MMA synthesis. The mutase presented here provides the solution: an enzyme which shifts a functional group from one position to another within a molecule. While in a post-doc position at the UFZ’s Department of Environmental Microbiology, Dr Thore Rohwerder and his mentor Dr Roland H. Müller discovered the enzyme in a newly isolated bacterial strain they found while searching for bacteria to break down the pollutant MTBE (methyl tertiary butyl ether).

The reason attributed by the awards judges to the industrial importance of the discovery was that altogether, in the medium to long term, up to ten percent of today’s demand for MMA could feasibly be produced by biotechnological means. The world market is over 3 million tonnes / 4 billion euro. It will take about four years to establish the bacterial system in a functioning technological process (pilot plant). In about ten years, a technological process is then conceivable, with an annual turnover of 150 to 400 million euro.

PMMA is a synthetic plastic developed in 1928 and today produced in great quantities. PMMA is often known colloquially as acrylic glass, as it is mainly used as a shatterproof, lightweight alternative to glass – for example, in protective goggles or vehicle lights. PMMA has many applications, including prosthetics, paints and adhesives. It is also sold under the brand names "Plexiglas®" (Evonik) and "Altuglas" (Arkema). In the GDR, names used for this plastic included "O-Glas" (for "organic glass") or "Piacryl" (named after the old producer in the GDR, Piesteritz nitrogen works near Wittenberg). The plastic is fragile, but very UV-resistant and thus weatherproof. Its high translucency and low weight mean that acrylic glass has to some extent replaced traditional glass. It was used for the roof of the Olympic stadium in Munich as far back as 1970. Experts predict that the demand for acrylic glass will grow even more in future – for example, for photovoltaic units.