Jun 4 2009

The sustainable design movement aims to reduce the negative impact of residential and commercial buildings on the environment. SABIC Innovative Plastics' growing portfolio of Lexan* polycarbonate (PC) multiwall sheet products are contributing to this movement and strengthen sustainable building designs by increasing energy conservation, improving working/living environments, and promoting recycling. Lexan sheet solutions can help architects, builders and contractors tap into the "green" building market, a $12-billion sector and a bright spot in the current construction industry slump. SABIC Innovative Plastics offers its customers a broad portfolio of Lexan multiwall sheet solutions for roofing, cladding and glazing.

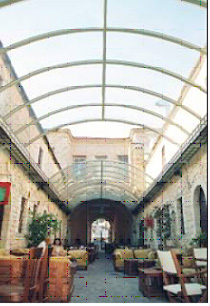

Curved, transparent Lexan* Solar Control sheet from SABIC Innovative Plastics helps absorb infrared (IR) and near-IR radiation from the sun, potentially reducing interior heat buildup by up to 40 percent. The tough virtually unbreakable SABIC Innovative Plastics material also helps protect restaurant customers from inclement weather conditions while allowing penetration of natural daylight into living, working or sitting areas

Curved, transparent Lexan* Solar Control sheet from SABIC Innovative Plastics helps absorb infrared (IR) and near-IR radiation from the sun, potentially reducing interior heat buildup by up to 40 percent. The tough virtually unbreakable SABIC Innovative Plastics material also helps protect restaurant customers from inclement weather conditions while allowing penetration of natural daylight into living, working or sitting areas

"Widespread concerns about the negative environmental effects of traditional building materials and methods are driving the adoption of sustainable design," said Darrell Hughes, general manager for SABIC Innovative Plastics, Specialty Film & Sheet. "Lexan multiwall sheet products can make a significant contribution by helping our customers achieve sustainable designs. For example, Lexan sheet far surpasses double- and triple-pane glass windows in thermal insulation performance, and its light weight saves energy in transportation and installation. Plus, it's 100 percent recyclable. By incorporating Lexan sheet into their designs, our customers can make any building more sustainable."

Conserving Energy

Sustainable design is the practice of creating healthier and more resource-efficient models of construction, renovation, operation, maintenance and demolition. Plastics can enhance sustainability in a variety of ways, including energy conservation and the potential for recyclability.

One key focus of sustainable design is energy efficiency. For example, builders must balance the increasing demand for designs that admit large amounts of light with concerns about energy costs. The use of specialized PC glazing instead of traditional glass can achieve both.

Lexan PC sheet allows natural daylight to enter a building, creating a more aesthetically pleasing working or living environment while saving on electricity for artificial lighting. However, while letting light in, the material also offers ultraviolet (UV) protection for occupant health, and exceptional thermal insulation to enhance energy conservation. With new Lexan Thermoclear* 9-wall sheet, U-values as low as .89 W/m2K (acc. ISO 10077 test) can be achieved - surpassing the insulation performance of double- and even triple-pane glass. Improved insulation reduces the use of energy for heating during cold periods and air conditioning during hot periods.

The use of specialized PC sheet that blocks infrared radiation (IR) can reduce the build-up of interior heat for lower energy consumption, while admitting plenty of light. This material is an excellent choice for skylights, walkways and roof domes where it is important to admit high light levels while reducing heat that would otherwise require air conditioning.

Another area where Lexan sheet conserves energy is in handling. This lightweight material - at least three times lighter than a comparably sized glass panel with the same thermal insulation value - saves fuel in shipping and installation. Less weight also allows Lexan sheet to be supported by lighter-weight glazing bars and substructure, reducing the amount of support material required.

Even during manufacture, Lexan sheet offers environmental advantages over glass. Typical operating temperatures during the sheet extrusion process are in the 240C range. Therefore the energy used during the extrusion process in which Lexan polycarbonate resin is converted into Lexan polycarbonate sheet, is just a fraction of the energy needed to manufacture the flat glass that goes into the same building & construction applications. During the Lexan polycarbonate sheet extrusion process, up to 15 percent of recycled content is used to produce virgin material.

Building a Case for LEED Certification

In the United States, the Leadership in Energy and Environmental Design (LEED) rating system is used to recognize whole-building sustainability. The LEED Green Building Rating System recognizes sustainable performance in major categories of a construction project and has become one of the most widely used systems in the United States. For example, many municipalities mandate that new public buildings must be designed and built with the goal of achieving LEED certification. Under the LEED system, credits are awarded for a number of different aspects of a project: sustainable sites; energy and atmosphere; materials and resources; and indoor environmental quality, to name a few.

By incorporating Lexan sheet glazing, roofing and cladding solutions into the design, builders can help win credits in the following areas:

- Sustainable Sites: Credit 8 - Light Pollution Reduction (1 point): Lexan SoftLite sheet, a new addition to SABIC Innovative Plastics' portfolio, offers light-diffusing characteristics that prevent direct-beam illumination from leaving the building interior. Also, the use of opaque Lexan sheet and Lexan multiwall sheet can block up to 100 percent of light pollution.

- Energy & Atmosphere: Credit 1 - Optimize Energy Performance (1 point each, up to 10 points): Lexan sheet provides superior winter and summer energy efficiency while transmitting diffused daylight.

- Materials & Resources: Credits 4.1 and 4.2 - Recycled Content (1 point each): Lexan sheet utilizes different percentages of pre-consumer recycled content that can help builders to obtain the credits.

- Indoor Environmental Quality: Credit 6.2 - Controllability of Systems (1 point): Lexan Solar Control IR sheet (monolithic and multiwall sheet versions) can help increase comfort in the building by up to 20 percent. Credits 8.1 and 8.2 - Daylight & Views (1 point each): Lexan sheet for walls, curtain walls and window replacement systems can easily and effectively integrate fixed and operable windows glazed with PC sheet for connection to the outdoors.

For additional information on Lexan sheet from SABIC Innovative Plastics, please visit www.sabic-ip.com.