Feb 22 2010

The Siemens Industry Solutions Division received an order from ArcelorMittal Bremen GmbH, a German flat-steel producer, to supply the electrical and automation equipment for the new secondary dedusting system in its LD steelworks. This will reduce the residual dust content of the offgas emitted to the environment to less than 10 mg/Nm3. The dedusting system is scheduled to be put into operation in the first quarter of 2011.

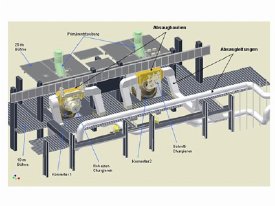

Internal structure of the secondary dedusting system (Source: ArcelorMittal Bremen GmbH).

Internal structure of the secondary dedusting system (Source: ArcelorMittal Bremen GmbH).

The construction of this dedusting system is part of a joint multi-location project involving not only ArcelorMittal Bremen but also the ArcelorMittal production facilities in Fos-sur-Mer and Florange, France. In Bremen, extraction hoods are to be mounted on the two converters of the LD steel works and connected to two extraction pipes, each with a diameter of 2.6 meters. Control flaps will be able to switch extraction between Converters Nos. 1 and 2. The extraction pipes will merge into a static mass cooler, where the exhaust gas will be cooled down from between 400 and 500°C to around 120°C to prevent damage to the downstream filter system. The exhaust gas will be cleaned to a final residual dust content of less than 10 mg/Nm³ before being finally discharged to the environment through a 54-meter-high smokestack. The secondary dedusting system is designed to have a maximum exhausting capacity of one million Nm³/h.

For this project, Siemens is providing the flap controllers, filter-cleaning system, dust-discharge system and fan. The drive solution will use Sinamics G150 frequency converters with IGBT power semiconductors with a power rating of 1,350 kW. The automation will be based on Simatic S7 PLCs. Personnel will use the InTouch HMI system for operator control and monitoring. Siemens will also be responsible for design engineering, installing the electrical equipment, and supervising commissioning and customer training.

The Luxembourg-based ArcelorMittal Corporation holds the controlling interest in ArcelorMittal Bremen GmbH. At its Bremen location, the corporation runs an integrated production plant consisting of a blast furnace and LD steelworks, hot- and cold-rolling mills, and two galvanizing lines. It produces hot and cold strip, as well as hot-dip galvanized thin-metal sheeting for customers in the automotive, construction, mechanical engineering and domestic appliance industries.

Further information about solutions for steel works, rolling mills and processing lines can be found at: http://www.siemens.com/metals