May 3 2010

Advanced Composites Group Ltd (ACG), part of the Composites Division of Umeco plc, will be displaying a Turbine Blade Demonstrator on its stand at the 2010 ALL-ENERGY show.

ACG has developed a range of rapid lay up prepreg formats specifically targeted at large structures in the alternative energy market. Building on its successful MTM®57 epoxy prepreg, the Group has developed two new 80 to 120°C curing variants, MTM®57-2 and MTM®57-3, which offer specific process advantages for renewable energy applications.

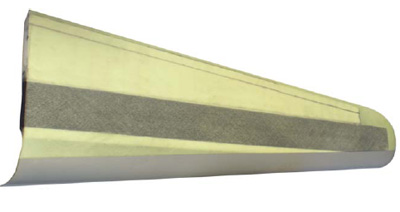

The Turbine Blade Demonstrator, which will take centre stage on the stand, uses ACG’s MTM57-2 on a 1200gsm glass ZPREG® rapid layup format combined with an in-mould surface primer film, MTF246, to form the glass fibre skins of the turbine blade. MTM57-2 heavyweight unidirectional (UD) carbon reinforcement is used to form the integrated spar, which is combined with a PVC foam core.

ZPREG has been optimised for ease of handling and does not require intermediate processing (debulking) prior to the final curing cycle, making it a one-shot, low cost operation.

ACG’s Turbine Blade Demonstrator reflects the materials and technologies applied by clients who have manufactured similar structures for use in demanding wind and tidal energy applications.

ACG’s sales representatives will be on hand to discuss specific requirements and advise on appropriate materials for the full spectrum of applications across the alternate energy sector.