Image Credit: Designua/Shutterstock.com

Since the early 20th Century, we have been in the midst of an energy crisis and environmental burden where global warming and limited energy resources are of the utmost concern. Thermoelectric ceramics are becoming increasingly studied for their potential use in energy generators and thermoelectric harvesting.

Thermoelectric Materials

Thermoelectric materials convert waste heat energy into electrical energy. The performance of a thermoelectric device depends on the type of material used and its thermal stability at elevated temperatures.

They need to have high electrical conductivity, low thermal conductivity, and must maintain a temperature gradient. They exhibit the thermoelectric effect in a strong or convenient form.

The thermoelectric effect refers to a phenomenon by which:

- A temperature difference causes an electrical potential, known as the Seebeck effect.

- An electrical potential leads to a temperature difference, known as the Peltier effect.

Currently used for thermoelectric systems in cooling and heating in niche applications, thermoelectric materials are also being studied as a means of regenerating electricity from waste heat.

Thermoelectric ceramics are crucial for energy conversion technology such as thermoelectric power generators; their modules consist of bulk oxide and foam materials of calcium cobalt oxide and calcium samarium manganese oxides. Their open porous foam structure means that they have a large surface area which allows for increased physical contact between themselves and the hot media, making them efficient electric power generators. Their structure also enables the design of efficient thermoelectric modules for waste heat sources involving gaseous and liquid mediums.

Thermoelectric Harvesting

Thermoelectric harvesting is also another hot research topic. In recent years there has been an increased interest in new applications of energy generation through thermoelectric harvesting, a trend which is expected to continue with the overall market for thermoelectric energy harvesters expected to reach $750m by 2022. Research is looking for ways to optimize oxide ceramics to allow them to reach their full energy-saving potential.

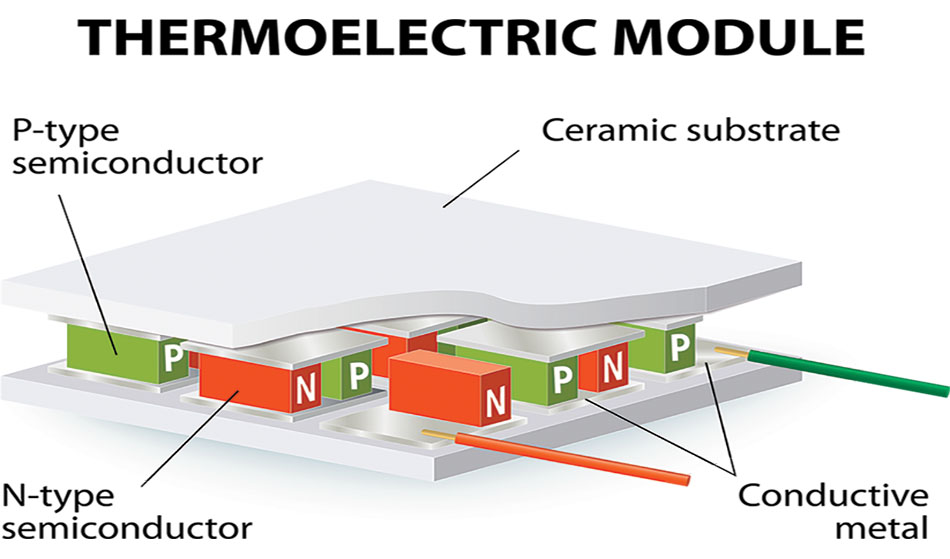

The current focus is on developing high-temperature p-type and n-type ceramic oxide thermoelectric materials and this will increase their electrical conductivity through doping and decrease thermal conductivity by introducing structure porosity.

Thermoelectric heat recovery technology can help reduce operating costs by increasing energy productivity and efficiency. However, the problem with current thermoelectric materials is that they do not operate efficiently at a temperature of about 300 °C – either that or they are too expensive. Ideally, energy needs to be captured between 700 °C and 1000 °C, but at these temperatures, either the material or the system begins to break down.

Markets for energy harvesting via thermoelectric ceramics include vehicle waste heat recovery, consumer and industrial applications, and military and aerospace applications.

Importance of Thermoelectric Harvesting

The American Environmental Protection Agency (EPA) estimates that only 15% of fuel energy is utilized to move a vehicle or run useful accessories like air conditioning; approximately 75% of the energy produced during peak combustion is lost in the exhaust and engine coolant as heat. Many car companies – including Volkswagen, Ford, and BMW, in conjunction with NASA – are all developing thermoelectric waste heat recovery systems in-house which could result in improvements in fuel economy. The technology could help to reduce a country’s carbon footprint and make cars more efficient, making the most of this untapped potential.

Consumer applications could be related to saving energy while cooking or heating the home, while industrial applications could make use of waste heat generated as part of the manufacturing process which would otherwise be lost.

Military and aerospace have been supporting thermoelectric research for decades and have already been utilizing radioactive, thermoelectric generators in space probes and satellites.

When the technology is fully developed, it could bring about a significant opportunity to recapture wasted energy generated at high temperatures in industrial processes, and during combustion in cars. It is expected that it could reduce fuel consumption of US drivers by over 10%, the equivalent of 2.1 million barrels of crude oil per day. The new thermoelectric systems employing advanced ceramic materials harvesting looks promising.

Sources and Further Reading

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.