Apr 10 2019

The hunt to avoid plastic from reaching landfills while at the same time meeting the demands of the food industry is full of hindrances.

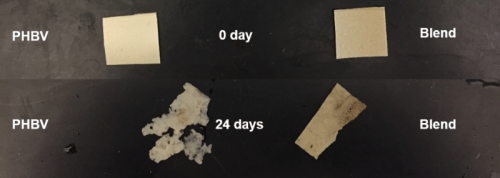

The new bioplastic and rubber blend devised by Ohio State researchers proved much more durable than the bioplastic on its own. (Image credit: Ohio State University)

The new bioplastic and rubber blend devised by Ohio State researchers proved much more durable than the bioplastic on its own. (Image credit: Ohio State University)

A biodegradable substitute for petroleum-based products has to satisfy all kinds of standards and, until now, efforts at feasible replacements from renewable sources have come across restricted success because of financial and processing restraints. Products developed until now have been too brittle for food packaging, which is one of the hindrances.

However, a new study carried out at The Ohio State University has demonstrated that by incorporating natural rubber with bioplastic in a new way, a considerably stronger replacement for plastic can be produced, one that is already gaining the attention of companies seeking to reduce their impacts on the environment.

Nearly all plastics, around 90%, are petroleum-based and cannot be biodegraded, a main environmental problem.

In new research reported in the journal Polymers, the team of scientists has reported success with a rubber-reinforced product obtained from microbial fermentation that they claim to function like traditional plastic. According to the researchers, this new research underlines the greatest ever success in this field.

Previous attempts at this combination were unsuccessful because the softness of the rubber meant the product lost a lot of strength in the process.

Xiaoying Zhao, Study Lead Author and Postdoctoral Researcher, Department of Food Science and Technology, The Ohio State University

In the new work, rubber was melted into a plant-based thermoplastic known as PHBV together with organic peroxide and another additive known as trimethylolpropane triacrylate (TMPTA).

The resulting product was 75% tougher and 100% more flexible when compared to PHBV as such—denoting that it is much easier to shape into food packaging.

Other research groups have blended rubber and PHBV; however, the products have been so fragile that they could not endure all the needs of a food package—from processing, through transporting, to handling in stores and homes, particularly containers that are used for freezing and subsequent microwaving, stated Yael Vodovotz, the senior author of the study and a professor of food science and technology at Ohio State.

With regard to plastic films normally used to wrap up everything from fresh yield to frozen foods, increased flexibility without a considerable loss of strength is mainly imperative, she stated.

Zhao stated that other efforts to produce this kind of rubber-enhanced bioplastic have decreased the strength of the PHBV by up to 80%; however, in this research, only 30% of the strength was lost—a much more controllable amount.

Toughness, which was increased, is different from strength, described Katrina Cornish, study co-author and an expert in natural rubber and professor of horticulture and crop science at Ohio State.

Imagine trying to pull a block of concrete apart with your hands. That’s testing its strength. But karate chopping it with your hand or foot is testing its toughness—how easily it breaks. You can never pull it apart, but if you’re strong enough you can break it.

Katrina Cornish, Study Co-Author and Professor, Horticulture and Crop Science, The Ohio State University

Currently, the scientists mainly focus on the potential use of different biodegradable—and otherwise environmentally conscious—materials that might be used as fillers to further reinforce the combination. They have made discussions to use the “cake” that is left behind after a fellow researcher extracts oil from used up coffee grounds. Tomato skins, as well as eggshells, are taken into consideration.

We want something that would otherwise go to waste that is sustainable and also relatively cheap.

Yael Vodovotz, Study Senior Author and Professor, Food Science and Technology, The Ohio State University

They are also focusing on the capability to attack two environmental issues simultaneously, by observing how invasive grasses that environmentalists are removing from waterways might play with the rubber-infused combination.

“We could dry them, grind them up and potentially use these grasses as a fibrous filler,” stated Vodovotz.

Apart from packaged foods, a bioplastic could possibly be employed in other food-related applications, for example, cutting boards and utensils.

Furthermore, the scientists are seeking to team up with colleagues outside of food science to take other applications into account for their product, such as developing building materials, gloves for those working in food service, or parts for airplanes and cars.

Since the team takes efforts to move its technology out of the lab and into the food industry, there will be many particulars to solve based on a company’s individual priorities and concerns, Vodovotz stated, and that may imply tinkering with the blend.

“As we get closer and closer to working with food manufacturers, there are specific questions our potential partners are asking,” stated Vodovotz. “We have to be very careful about what we use in this process in order to meet their needs, and they have very specific parameters.”

The funding for the research was offered by the Center for Advanced Processing and Packaging Studies.