Jul 4 2019

As a measure to tackle climate change, poligy’s objective is to turn industrial and solar waste heat into electricity at a lesser cost than earlier technologies through a new material called Bipolymers. According to specialists, this pioneering material could transform the conversion of industrial and solar heat into electricity.

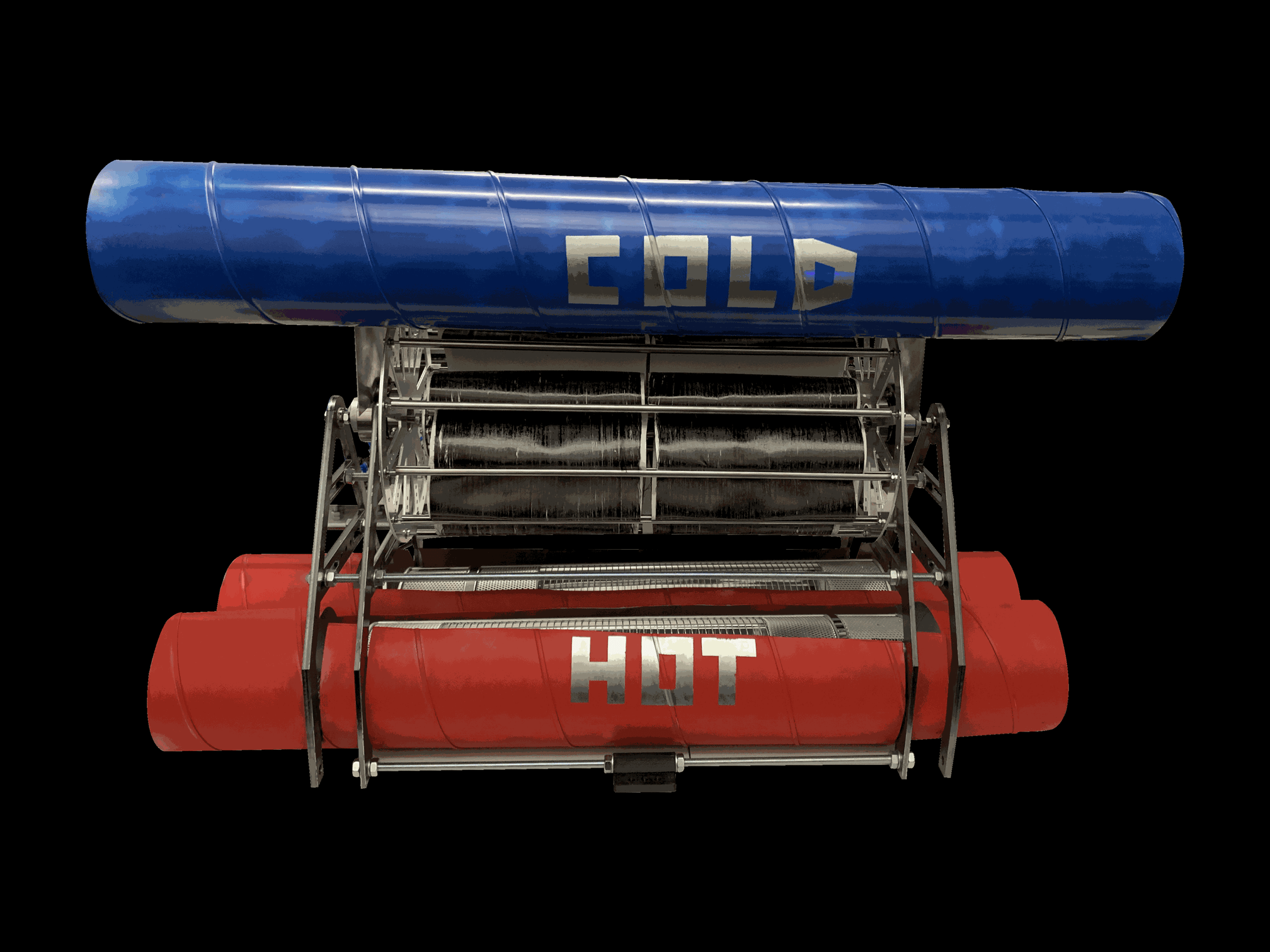

Bipolymer waste heat module. (Image credit: poligy)

Bipolymer waste heat module. (Image credit: poligy)

- Lucrative conversion of industrial waste heat into electricity

- More eco-friendly than photovoltaic systems

- Awards: StartupCon 2018, Handelsblatt, etc.

- Research objective: Lesser costs for consumers

So as to tackle climate change, green energy must become considerably economical for consumers and the industry. The solution to this is currently being provided by business chemist Martin Huber with a newly produced plastic called Bipolymer.

According to professionals, this ground-breaking material could transform the regeneration of industrial and solar heat into electricity. To commercialize his technology, Huber has partnered with entrepreneur Artur Steffen. The two of them established the start-up company poligy.

Low-Cost Electricity from Solar Heat and Industrial Waste Heat

Bipolymers turn heat into electricity inexpensively, both for solar heat on house roofs or industrial waste heat from factories, power plants, or data centers. According to the Federal Environment Agency, about 45% of the industrial waste heat produced during manufacture processes remains unexploited (source: press release of the German Environment Agency). Huber’s aim is to turn industrial and solar waste heat into electricity more economically than any earlier technologies through Bipolymers.

Functionality of Bipolymers

Business chemist Martin Huber invented the Bipolymers, which are two-ply plastic strips. They form a band or wheel in solar modules and thermal engines. The plastic strips contract and expand according to the temperature, developing a movement in the belt or wheel, which then produces electricity via a generator.

Until now, there has been no cheap technology alternative that can produce green electricity from waste heat at temperatures between 50 °C and 200 °C. In addition, the thermal engines and Bipolymers can be produced in large quantities and at low cost.

Martin Huber, Business Chemist and Creator of Bipolymers, poligy

As the facilities needed for the manufacture of Bipolymers are already available, its production does not incur huge costs. Moreover, only a small amount of energy is needed during the manufacture of this material.

Research Goal: Lower Acquisition Costs for Consumers

Furthermore, the costs of a Bipolymer heat engine are lesser than photovoltaic systems. Huber and his team are examining whether the Bipolymer modules can create hot water, electricity, and heat while storing the energy they create. In the case of photovoltaic systems, consumers will have to frequently purchase costly additional systems such as solar thermal systems and special energy storage devices to heat water.

On the other hand, Bipolymers can be recycled more cheaply than solar cells because, unlike photovoltaic systems, our systems do not contain traces of toxic heavy metals. This is also good for the environment.

Martin Huber, Business Chemist and Creator of Bipolymers, poligy

Billions in Key Technology for Industrial Waste Heat

According to the German Energy Agency, industries in just Germany could save about 37 million tons of climate-damaging CO2 and five billion euros yearly by preventing and utilizing industrial waste heat. It would also create a potential of 125 terawatt hours of heat (source: German Energy Agency).

According to a research done by Global Market Insights Inc. in early 2019, the worldwide waste heat market will expand from $40 billion in sales in 2018 to over $80 billion in 2025. For Germany, market researchers anticipate a market turnover of five billion dollars in 2025. (source: press release global market insights).

Significance for Paris Climate Targets

The aim of the 2015 Paris Climate Agreement is to lower global warming to much below 2 °C by 2100, compared with the pre-industrial era. To accomplish the Paris climate targets, the esteemed American journal Science estimates that global emissions must slowly drop to five billion metric tons by 2050 (source: Wikipedia).

For comparison: According to the Federal Environment Agency, CO2 emissions in Germany in 2018 amounted to 865.6 million tons (source: German Environment Agency). Universal CO2 emissions in 2018 totaled to 33.1 billion metric tons (source: Internationalen Energieagentur IEA). The 28 Member States of the EU amounted to 4.29 billion metric tons per year (source: German Environment Agency).

Multiple Awards: Bipolymers Could Revolutionize Power Generation

Poligy’s invention received the “Future Materials” award from the Handelsblatt newspaper, among others. At StartupCon 2018, Germany’s biggest start-up fair, poligy won the international Chem Startup Award in the “New Materials” category. Furthermore, poligy was added into the Top 100 list of “Start Up Energy Transition (SET)” as one of the world’s leading energy start-ups.

Research and Development Funding: Digital Securities Issue on July 1st, 2019

From July 1st, 2019, digital securities based on blockchain technology will be issued by poligy to fund the additional development of Bipolymer systems until market maturity. The digital securities also referred to as security tokens can be invested by experienced investors and specifically by industrial partners such as tech groups and energy manufacturers.

The investments are important. However, as important are the know-how and commitment of our investors in order to bring our products to market quickly. We have therefore joined forces with international energy and chemical companies to develop the product.

Artur Steffen, Co-Founder and CEO, poligy