Nov 27 2019

A new study has found that a technology created by the U.S. Department of Energy’s Oak Ridge National Laboratory and optimized by Vertimass LLC to convert ethanol into fuels useful for shipping, aviation, and other heavy-duty applications can be cost-competitive with traditional fuels, and also retain the sustainability benefits of bio-based ethanol.

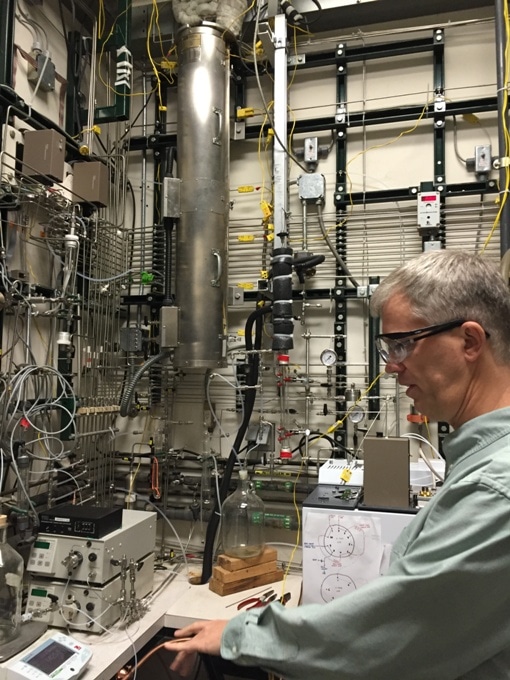

A pilot reactor, developed by Vertmass and located at TechnipFMC, can scale up the process that converts ethanol into fuels suitable for aviation, shipping, and heavy-duty applications. Image Credit: TechnipFMC

A pilot reactor, developed by Vertmass and located at TechnipFMC, can scale up the process that converts ethanol into fuels suitable for aviation, shipping, and heavy-duty applications. Image Credit: TechnipFMC

ORNL collaborated with technology licensee Vertimass and researchers from 10 other institutions on a techno-economic and life-cycle sustainability study of the process—single-step catalytic conversion of ethanol into hydrocarbon blendstocks that can be mixed with diesel, jet, or gasoline fuels to bring down their greenhouse gas emissions. This innovative technology is known as Consolidated Dehydration and Oligomerization (CADO).

The study, reported in Proceedings of the National Academy of Sciences, revealed that this single-step process for changing wet ethanol vapor could yield blendstocks at $2/gigajoule (GJ) at present and $1.44/GJ in the future as the process is improved, which includes operating and annualized capital costs.

Thus, the blendstock would be competitive with traditional jet fuel synthesized from oil at historically high prices of around $100/barrel. At $60/barrel oil, the use of current renewable fuel incentives result in price parity, the study discovered.

The conversion utilizes a type of catalyst known as a zeolite, which directly creates longer hydrocarbon chains from the original alcohol, (here, ethanol), substituting a conventional multi-step process with one that uses minimal energy and is extremely efficient.

The robustness of the catalyst enables direct conversion of wet ethanol, which greatly simplifies the process, reduces the cost of ethanol purification and makes hydrocarbon blendstock production costs competitive based on the analysis.

Zhenglong Li, Project Collaborator and Staff Scientist for Biomass Catalysis, ORNL

This single-step catalysis was successful at a laboratory scale, and additional testing and enhancements by Vertimass brought about even higher product yields when scaled up 300 times by applying commercial catalyst formulations. The conversion operation could be combined into new biofuels plants or set up as bolt-on technology to current ethanol plants with marginal new capital investment, the scientists observed.

Advanced biofuels have potential as clean-burning, carbon-neutral renewable energy sources. The aim is to develop advanced liquid biofuels that can make the most of the currently available pipeline delivery infrastructure and can be used in current or advanced engines without performance loss.

The fuels are especially appealing to help decrease net carbon emissions in heavy-duty engines such as those in ships, aircraft, and large commercial vehicles where electrification is tough.

Subject to existing standards, the advanced biofuel could be mixed at 20% with petroleum-derived jet fuel and slightly higher for gasoline, conditional on certification and verification.

In the meantime, a life-cycle study of the conversion process discovered that its greenhouse gas emissions profile is analogous to that for the ethanol added to the process.

The sustainability of bio-derived ethanol, now mostly produced from corn in the United States but with some now being made from corn stover and eventually dedicated biomass feedstocks like switchgrass, carries through with the catalytic process.

Brian Davison, Chief Science Officer, DOE’s Center for Bioenergy Innovation (CBI), ORNL

Davison is a collaborator on the project. CBI is pursuing particular research targets for a flourishing bioeconomy: advanced processes to disintegrate and turn plants into specialty biofuels, sustainable biomass feedstock crops, and valuable bioproducts, such as chemical feedstocks, produced from the lignin residue after bioprocessing.

Our scientists constantly push the boundaries of what’s possible to deliver breakthroughs for clean energy. The conversion of ethanol into hydrocarbon blendstocks takes advantage of an abundant domestic energy resource while supporting the development of thriving American bioeconomies.

Moe Khaleel, Associate Laboratory Director for Energy and Environmental Sciences, ORNL

Vertimass refined the original, lab-scale process by developing inexpensive forms of the catalyst, and more than doubling the liquid fuel production, the paper observed.

The paper describes the refinements as well as outcomes from analyses by Argonne National Laboratory, the National Renewable Energy Laboratory, Vertimass, and ORNL in partnership with Dartmouth, the Federal Aviation Administration, Boeing, Pennsylvania State University, University of California-Riverside, Imperial College of London, the Brazilian Bioethanol Science and Technology Laboratory, and the Brazilian Center for Research in Energy and Materials.

This research shows how ethanol, in addition to being a valuable fuel for cars, can be an effective intermediate for sustainable production of low-cost fuels for air travel and heavy-duty vehicles. The integration of biological and catalytic technologies shown here reflects the power of such hybrid systems.

Lee Lynd, Study Corresponding Author and Professor, Dartmouth College

Lynd collaborated on this research.

The preliminary discovery was supported by the Center for Bioenergy Innovation at ORNL, which in turn is aided by the DOE Office of Science. Scale-up research and development were partially supported by the DOE Office of Energy Efficiency and Renewable Energy and by Vertimass.