Aug 19 2020

People may find it difficult to drive over potholes, which can cause damage to automobile tires, suspensions, and wheels, costing billions of dollars every year.

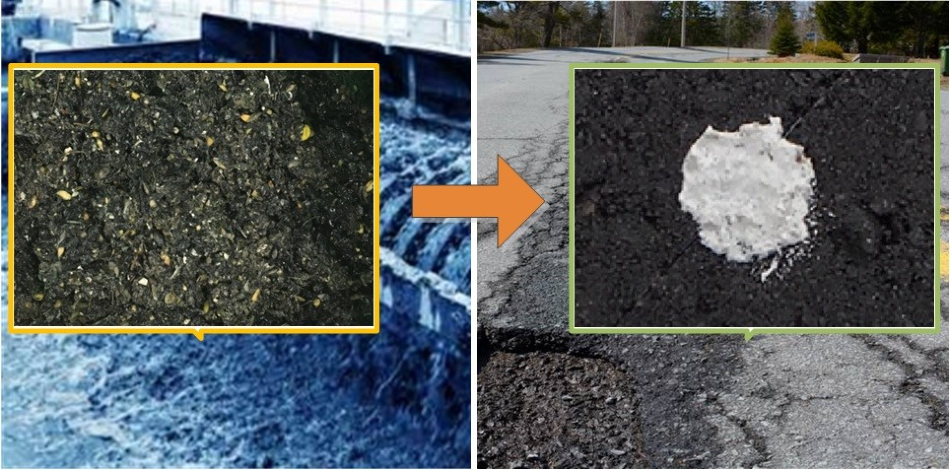

Researchers are turning grit from wastewater (left) into a ceramic mortar that can be used as a pothole filler (right). Image Credit: Zhongzhe Liu.

Researchers are turning grit from wastewater (left) into a ceramic mortar that can be used as a pothole filler (right). Image Credit: Zhongzhe Liu.

At present, the road crews are using hydrocarbon-containing asphalt to fill in these potholes, but this material tends to leach out and pollute the surroundings.

A team of researchers has now reported a novel method to repair roads in an environmentally friendly manner. This method involves using the remains of wastewater treatment—known as grit—that is generally discarded in landfills.

The team will present the study results at the American Chemical Society (ACS) Fall 2020 Virtual Meeting & Expo. The meeting is being held through Thursday, August 20th, 2020, and features over 6000 presentations on a broad range of science-related topics.

We had an idea to divert wastewater grit from landfills and turn it into a marketable product. We formulated it into a ceramic mortar that could be used as a patch for pothole repair.

Zhongzhe Liu, PhD, Assistant Professor, California State University, Bakersfield

Called grit assisted patch (GAP), the substance is ultimately safer for the environment when compared to hydrocarbon-based asphalt.

However, grit is a bulky, non-biodegradable solid and should be processed to convert it into GAP. Wastewater containing food scraps, sewage, and other waste is first processed at treatment plants. This process results in clean water that is discharged into waterways, but the preliminary treatment also yields solids that mostly contain sand and gravel, and this is called grit.

Since grit contains impurities and pathogens that render it unsuitable for direct recycling, it is often transferred to a landfill and buried.

Liu from the California State University, Bakersfield, and his colleagues were searching for ways to make this grit useful, probably as a road material. The team eventually decided to add grit to a chemically bonded phosphate ceramic (CBPC). CBPCs are often used for treating radioactive or hazardous waste for disposal, but none has used this material on wastewater products, to date.

Since a CBPC includes ingredients that would deactivate microorganisms, the team believed that this might be an excellent way to destroy microbes and create a material that could be safely used on roads.

In the first step of making a CBPC, we mix the wet grit with calcium oxide and magnesium oxide, which form an alkaline grit slurry that prevents the proliferation of pathogens. The second step is to add a weak acid, potassium dihydrogen phosphate, into the pathogen-minimized alkaline slurry to form the grit-CBPC mortar.

Zhongzhe Liu, PhD, Assistant Professor, California State University, Bakersfield

Traditional asphalt patch comprises bitumen, which is a black, sticky residue resulting from petroleum distillation. The traditional patch has polycyclic aromatic hydrocarbons (called PAHs) that pose a threat to human health. But this environmental concern is eliminated by a grit-formulated patch since its matrix is made up of magnesium and calcium oxides that are not harmful to people.

Until now, the team has investigated the performance of the GAP in a laboratory setting, demonstrating that it has a compressive strength similar to that of asphalt pavement, and according to them, its longevity will be better than that of asphalt-based patches.

Based on these primary results, the researchers have now filed a patent for a GAP. Meanwhile, the team is working to enhance the compressive strength of the GAP even more, so that it could possibly be utilized in other applications such as building wheel stops at the end of parking spaces.

The subsequent step for commercializing GAP as a pothole patch is to assess its bond strength when it comes into contact with the prevalent pavement, and its durability when subjected to adverse environments.

At present, the researchers are working on demonstration-scale experiments to field test the GAP on an operational highway with standard traffic. If needed, they will investigate additives to further enhance the durability and mechanical properties of the latest material.

The researchers have also planned to make a side-by-side comparison of traditional patch and GAP to gain complete insights into the advantages provided by the latter in terms of economic benefit and carbon footprint.

The team acknowledged funding and support from the Milwaukee Metropolitan Sewerage District.