Reviewed by Danielle Ellis, B.Sc.Jan 24 2022

Energy systems not only fuel people’s daily lives but also generate wasted heat — such as heat that is emitted off of exhaust pipes on vehicles and hot water pipes in buildings.

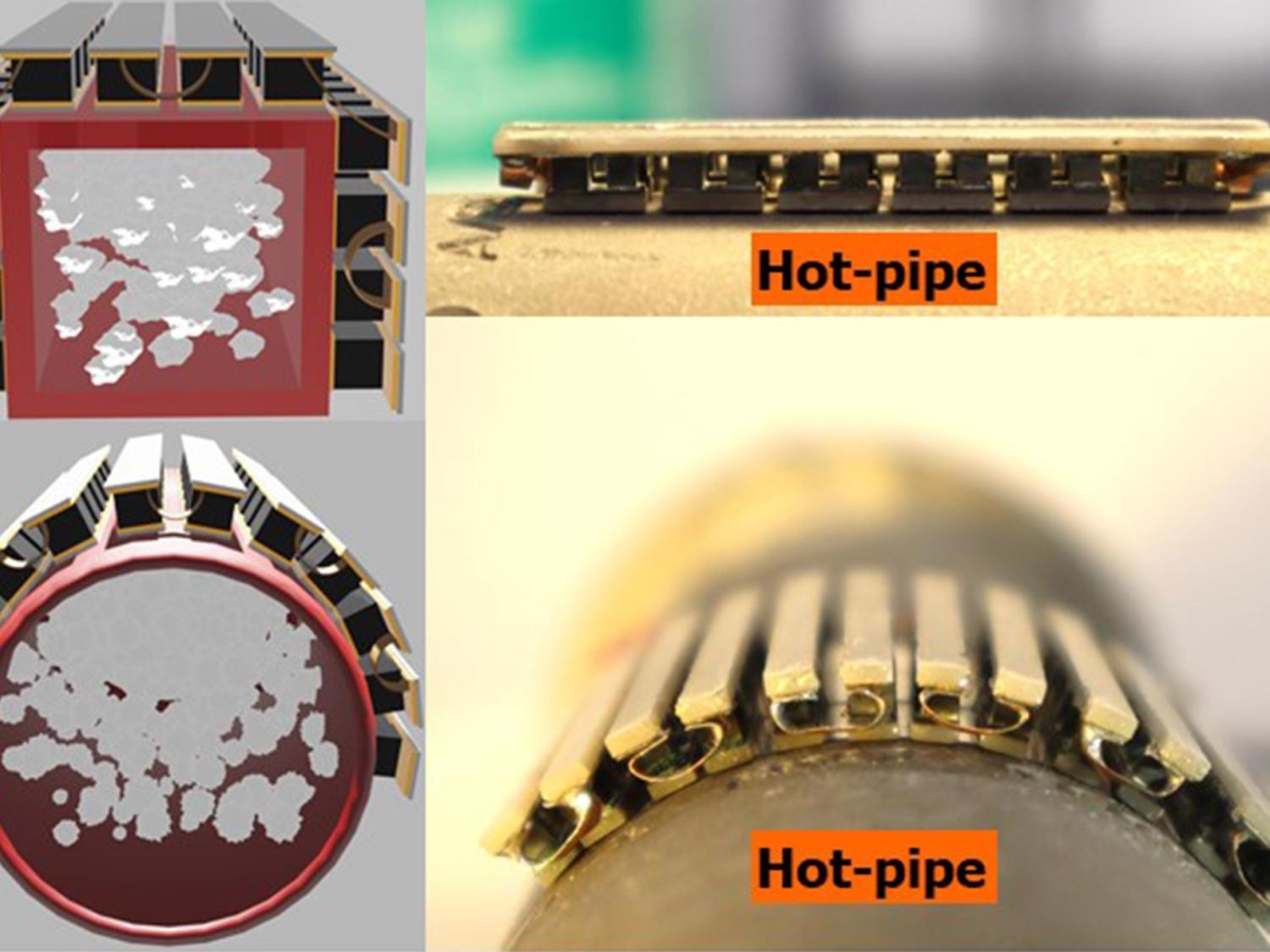

A new flexible thermoelectric device can wrap around pipes and other hot surfaces and convert wasted heat into electricity. (Image Credit: Penn State).

A new flexible thermoelectric device can wrap around pipes and other hot surfaces and convert wasted heat into electricity. (Image Credit: Penn State).

A new adaptable thermoelectric generator can be wrapped around pipes and other hot surfaces to turn wasted heat into electricity more competently than formerly possible, according to researchers at Penn State and the National Renewable Energy Laboratory.

A large amount of heat from the energy we consume is essentially being thrown away, often dispersed right into the atmosphere. We haven’t had cost-effective ways with conformal shapes to trap and convert that heat to useable energy. This research opens that door.

Shashank Priya, Associate Vice President for Research and Professor of Materials Science and Engineering, Penn State University

Penn State scientists have been making efforts to increase the performance of thermoelectric generators — devices that can turn differences in temperature into electricity. When the devices are positioned close to a heat source, electrons traveling from the hot side to the cold side generate an electric current, the researchers explained.

In previous work, the researchers developed rigid devices that were more efficient compared to commercial systems in high-temperature applications. At present, the team has formulated a new manufacturing process to create flexible devices that provide higher power output and efficiency, the researchers said.

These results provide a promising pathway toward widespread utilization of thermoelectric technology into waste heat recovery application. This could have a significant impact on the development of practical thermal to electrical generators.

Wenjie Li, Assistant Research Professor, Penn State University

Flexible devices are an ideal fit for most waste heat sources, such as pipes in residential and industrial buildings and on vehicles, the researchers stated. Moreover, they do not have to be stuck to surfaces like traditional, rigid systems, which further reduce efficiency.

In tests being carried out on a gas flue, the new device demonstrated a 150% higher power density than other advanced systems. A scaled-up version, about 3-inches squared, was able to keep a 115% power density advantage. That version demonstrated a total power output of 56.6 watts when positioned on the hot surface, the researchers said. The researchers reported their findings in the journal Applied Materials & Interfaces.

Think about an industrial power plant with pipes hundreds of feet long. If you can wrap these devices around an area that large, you could generate kilowatts of energy from wasted heat that’s normally just being thrown away. You could convert discarded heat into something useful.

Shashank Priya, Associate Vice President for Research and Professor of Materials Science and Engineering, Penn State University

Thermoelectric devices are composed of small couples, each looking like a table with two legs. Several of these two-leg couples are linked together, usually forming a flat, square system.

In developing the new device, the researchers positioned six couples along a thin strip. They then used adaptable metal foil to link 12 of the strips together, producing a device with 72 couples. Liquid metal was added between the layers of each strip to enhance device performance, the researcher said.

As you scale up these devices, you often lose power density, making it challenging to fabricate large-scale thermoelectric generators. This illustrates the extraordinary performance of our 72-couple device.

Bed Poudel, Associate Research Professor, Penn State University

The 72-couple device displayed the maximum reported output power and device power density from a single thermoelectric generator, the researchers stated.

The gaps between the strips offer the flexibility to wrap around shapes such as pipes. The gaps also permit for flexibility in varying the fill factor, or the ratio between the area of the device and the area of the thermoelectric material, which can be used to enhance thermoelectric devices for various heat sources, the researchers explained.

Other Penn State scientists involved in the study were Amin Nozariasbmarz, assistant research professor; Han Byul Kang and Hangtain Zhu, postdoctoral scientists; and Carter Dettor, a former graduate student.

Ravi Anant Kishore, a research engineer at National Renewable Energy Laboratory, also contributed.

All the authors contributing to this research were supported through the Department of Energy, Office of Naval Research, Army Research Office, National Science Foundation, and Defense Advanced Research Projects Agency.

Journal Reference:

Wenjie, L., et al. (2021) Conformal High-Power-Density Half-Heusler Thermoelectric Modules: A Pathway toward Practical Power Generators. ACS Applied Materials & Interfaces. doi.org/ 10.1021/acsami.1c16117.