Mar 29 2009

Using two different types of chemical etching to create features at both the micron and nanometer size scales, researchers at the Georgia Institute of Technology have developed a surface treatment that boosts the light absorption of silicon photovoltaic cells in two complementary ways.

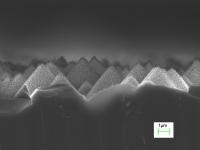

This image shows silicon pyramid structures etched for one minute using hydrogen fluoride/hydrogen peroxide/water solution. The resulting structure has roughness at the micro and nanometer scales.

This image shows silicon pyramid structures etched for one minute using hydrogen fluoride/hydrogen peroxide/water solution. The resulting structure has roughness at the micro and nanometer scales.

The surface treatment increases absorption both by trapping light in three-dimensional structures and by making the surfaces self-cleaning – allowing rain or dew to wash away the dust and dirt that can accumulate on photovoltaic arrays. Because of its ability to make water bead up and roll off, the surface is classified as superhydrophobic.

"The more sunlight that goes into the photovoltaic cells and the less that reflects back, the higher the efficiency can be," said C.P. Wong, Regents' professor in Georgia Tech's School of Materials Science and Engineering. "Our simulations show that we can potentially increase the final efficiency of the cells by as much as two percent with this surface structure."

Supported by the National Science Foundation (NSF) and the National Electric Energy Testing Research and Applications Center (NEETRAC) at Georgia Tech, the research will be described March 24th at the Spring 2009 National Meeting of the American Chemical Society in Salt Lake City.

The silicon etching treatment mimics the superhydrophobic surface of the lotus leaf, which uses surface roughness at two different size scales to create high contact angles that encourage water from rain or condensation to bead up and run off. As the water runs off, it carries with it any surface dust or dirt – which also doesn't adhere because of the unique surface properties.

In the silicon surface treatment, the two-tier roughness – created with both micron- and nano-scale structures – works in the same way as the lotus leaf, minimizing contact between the water or dust and the surface, Wong noted.

"When a water droplet reaches the surface, it sits on top of this two-tier roughness and only about three percent of it is in contact with the silicon," he explained.

Preparation of the superhydrophobic surface begins with use of a potassium hydroxide (KOH) solution to etch the silicon surface. The solution preferentially removes silicon along crystalline planes, creating micron-scale pyramid structures in the surface.

An e-beam process is then used to apply nanometer-scale gold particles to the pyramid structures. Using a solution of hydrogen fluoride (HF) and hydrogen peroxide (H2O2), a metal-assisted etching process – with gold as the catalyst – produces the nanometer-scale features. The feature size is controlled by the diameter of the gold particles and the length of time the silicon is exposed to the etching.

Finally, the gold is removed with a potassium iodide (KI) solution and the surface coated with a fluorocarbon material, perfluorooctyl tricholosilane (PFOS).

The combination of increased light absorption from the textured surface and the self-cleaning ability both help boost absorption of sunlight hitting the silicon surface.

"A normal silicon surface reflects a lot of the light that comes in, but by doing this texturing, the reflection is reduced to less than five percent," said Dennis Hess, a professor in the Georgia Tech School of Chemical and Biomolecular Engineering. "As much as 10 percent of the light that hits the cells is scattered because of dust and dirt of the surface. If you can keep the cells clean, in principle you can increase the efficiency. Even if you only improve this by a few percent, that could make a big difference."

Even in desert areas where constant sunlight provides ideal conditions for photovoltaic arrays, nighttime dew should provide enough moisture to keep the cells clean, Wong said.

The research team, which also included Yonghao Xiu, Shu Zhang and Yan Liu, is working with Georgia Tech's University Center of Excellence for Photovoltaics Research and Education -- headed by Professor Ajeet Rohatgi of Georgia Tech's School of Electrical and Computer Engineering -- to evaluate the surface treatment with real solar cells.

However, adoption of the superhydrophobic surface treatment will ultimately depend on its long-term robustness and cost.

"Because the structures are so small, they are fairly fragile," Hess noted. "Mechanical abrasion to the surface can destroy the superhydrophobicity. We have tried to address that here by creating a large superhydrophobic surface area so that small amounts of damage won't affect the overall surface."

Large scale cost estimates haven't yet been done, but Hess said the additional etching and vacuum deposition steps shouldn't add dramatically to the already complex manufacturing process used for fabricating silicon PV cells.

In addition to photovoltaic cells, the surface treatment could be used to create anti-bacterial coatings on medical equipment, micro-electromechanical devices that don't stick together, and improved microfluidic devices.