Apr 28 2014

Rice University engineering students think it’s a shame to waste energy, especially in space. So a team of seniors invented a device that turns excess heat into electricity.

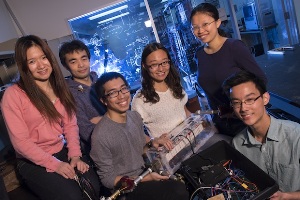

Rice engineering students have created an exchange system that can return energy in the form of electricity to spacecraft from waste heat. From left, Mira Chen, Lee Xiong, Justin Dong, Sophie Xu, Yixuan Wang and Shota Makino. Photo by Jeff Fitlow

Rice engineering students have created an exchange system that can return energy in the form of electricity to spacecraft from waste heat. From left, Mira Chen, Lee Xiong, Justin Dong, Sophie Xu, Yixuan Wang and Shota Makino. Photo by Jeff Fitlow

Heat created by electronics onboard the International Space Station (ISS) now gets tossed overboard into the void. But new technology to turn heat into power would make it possible to put it back to work to run the myriad systems onboard.

The senior engineers who call themselves “Team Space Ring” are using thermoelectric generators that transfer heat from cooling pipes like those used to radiate it into space. The generators serve several functions: They could perform their primary task of generating electricity while cooling the station and its components, or they could reverse the process and actually send hot coolant at the desired temperature back into the station.

Team members brought a mix of talents to the project, one of six sponsored by NASA’s X-Hab Academic Innovation Challenge. Among them are two electrical engineering majors, Mira Chen and Lee Xiong; two mechanical engineers, Sophie Xu and Yixuan Wang; and two double majors, Shota Makino (electrical engineering and computational and applied math) and Justin Dong (mechanical engineering and computational and applied math). They were advised by Gary Woods, a professor in the practice of computer technology and electrical and computer engineering at Rice.

Team of engineers at Rice work on harvesting energy from heat in space

The electrical engineers had bigger ideas at first. “One side of the moon is always dark and one side light, and the temperature difference is 200 degrees Celsius,” said Lee at the team’s station at Rice’s Oshman Engineering Design Kitchen. “We were joking about it: What if we could put a ring around the moon? That would be awesome!

“But NASA told us that would be impractical without a base there, and they wouldn’t have one anytime soon. But they said, ‘If you can scale it down a bit …’”

Their NASA advisers immediately saw the idea’s potential. “The team’s approach is not directly applicable to spacecraft, but the concept is. We plan to include the findings of the research in our next opportunity for power systems design,” said Patrick George, a project manager at NASA’s Glenn Research Center in Cleveland. He said such a system applied to the ISS would provide more energy for experiments and other operations and would increase the life of key components.

The thermoelectric generators — small, flat units wired together and stuck to a square pipe — convert heat to electricity through the Seebeck effect, which determines electron flow inside the material depending on the flow of heat to cold. The larger the difference in temperature, the greater the amount of current produced.

The prototype’s generators are efficient enough now to power its onboard pumps, but team hopes the conversion rate from state-of-the-art generators — about 15 percent — would be enough to send excess electricity back to a spacecraft for other uses as well, according to the team.

Conversely, applying energy from outside to the system draws upon the Peltier effect to return heat to the system.

The students explained that in space applications, the generators would be placed inside a double-pipe heat exchanger through which hot fluid (carrying waste heat from electronics) and cold fluid (a coolant like ammonia) would flow. For safety, they used boiling and ice water in lab experiments on a 20-generator system that provided about 25 volts of electricity, enough to make the system self-sustaining. Before graduation, they plan to install an additional 20 generators.

While the Rice team’s idea may never make it to the ISS, NASA is taking a long view, looking for technologies that will make deep-space missions possible. “To be selected as one of the six university team participants for the X-Hab challenge meant that NASA would have high expectations from the team at Rice University,” George said. “The team has put a lot of energy into the task, which translates to good ideas for NASA to consider. Our expectations were met!”